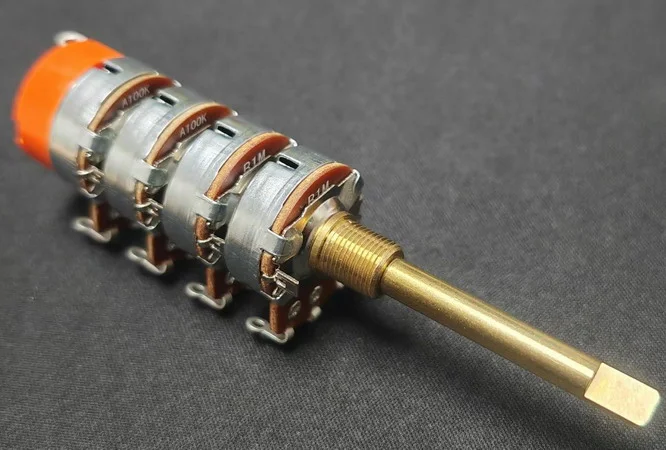

As shown above, the upper one is a quad-gang dual-control potentiometer used in vintage Sansui products (Japan). It is a carbon film / carbon track type. It can control volume and balance at the same time, while saving space. The lower one is a conductive plastic multi-gang potentiometer used in military control systems. The section near the shaft can be stacked to add more gangs based on the customer’s needs. The exact application is unknown.

1. Introduction: The customer’s concern may not be performance. It may come from pure passion.

Recently, I received inquiries from two customers. I had a “time travel” feeling. (One of my first books for learning potentiometers was published in 1975 by an American author, Carl David Todd.) It felt like I was watching an early carbon-pile concept evolve, step by step, into today’s real products.

When I look at a vintage ALPS potentiometer, I have a very clear feeling: this was not a “compromise under limitations.” It was a physical design that was carefully thought through at that time (about 50 years ago).

That is exactly why these old potentiometers are still interesting today. From a manufacturing view, it is mainly a cost topic now. In many classic Japanese tube amplifiers and early hi-fi equipment, this structure was almost a “default choice.”

2. Let’s start with common multi-gang potentiometers today.

Multi-gang potentiometers are still very common in today’s audio equipment.

The most typical use is one knob controlling the volume of multiple channels at the same time.

As shown above, this type usually has a few clear structural features:

- One single shaft

- Multiple fully independent resistive elements

- Similar electrical behavior across the gangs

- Mechanical linkage for synchronized rotation

From a manufacturing point of view, this is a very mature solution.

The structure is clear. It is easy to repeat. It fits mass production well.

At this stage, “multi-gang” mainly means synchronized control. The idea itself is not complicated.

3. Multi-gang potentiometers did not start from audio.

If we look further back, we will find that multi-gang potentiometers did not originate from the audio industry.

In early analog systems, people faced one core problem:

How to change multiple electrical parameters with one action, and keep them in sync.

In that era, there was no MCU, no encoder, and no software compensation. “One shaft + synchronized change” was a very reliable and very direct control method. Of course, synchronization could still be affected by things like linearity, and the service life of each resistive element. But it was still a very good solution.

From this perspective, multi-gang structures first solved a synchronization problem, not sound, tone, or any so-called “premium experience.”

The audio industry simply saw the value early, and pushed this structure to an extreme, and also to a very mature level.

4. Multi-gang and multi-control designs in Japanese audio products (1970s–1980s)

If we go back to Japanese audio products in the 1970s–1980s, we can see multi-gang structures being further “deepened.”

Taking Sansui and similar tube amplifiers and hi-fi systems as examples, in those designs, multi-gang potentiometers were not only used for multi-channel synchronization. They also started to combine different control logics, such as volume and left-right balance.

At that stage, Japanese potentiometer makers like ALPS offered many multi-gang solutions with complex structures but very high reliability.

Still multi-gang, still one shaft rotation.

But the resistive distribution inside each gang could be different.

It was designed on purpose for different control targets.

When I first realized this, I wasn’t surprised by the technical difficulty. Anyone who knows basic circuits knows you can use jumper wires (point-to-point wiring) and several separate potentiometers to solve it. What surprised me was their choice: they compressed all these control problems into one physical structure.

Even with today’s manufacturing capability, this choice still leaves a strong impression on me and my colleagues.

5. What these audio multi-gang designs were really solving back then

If we judge these multi-gang multi-control structures without the historical context, it is easy to misunderstand them.

At that time:

- No digital volume control

- No DSP-based balance compensation

- Almost no software-level correction later

All control had to be continuous, analog, and predictable.

More importantly, sound is for human ears. People care about smooth volume change. People care about returning to center balance easily. People also care if the knob “stays stable” at certain positions. These things cannot be fully fixed by the system. Well, each listener is different.

So designers had to solve these points inside the component itself:

- Use the resistive track distribution to control the rate of change

- Use the wiper structure to affect the overall stability feel

- Use mechanical synchronization to keep left and right behavior consistent

Under these conditions, multi-gang multi-control was not “unnecessary added complexity.” It was a direct and practical choice in that era.

6. Why it later moved back to “multi-gang, single control”

To be clear, these multi-gang multi-control designs did not disappear because they were “bad.”

As system design evolved, control logic gradually moved from inside the component to the system level. Functions like volume, balance, and gain were separated into different modules.

At the same time, manufacturing priorities also changed:

- Clearer requirements for consistency and yield

- More focus on maintainability and interchangeability

- Changes in cost structure and supply chain

In this context, simplifying structures and splitting functions was a natural evolution.

This was not a denial of early designs. It was a choice after the whole system upgraded.

7. A different “multi-gang” path in industrial and military systems

In industrial and military applications, multi-gang potentiometers still exist, but the focus is clearly different.

Here the focus is not operating feel or listening feel. The focus is:

- Long-term stability

- Parameter consistency

- Verifiable and repeatable performance

- As long a service life as possible

- Performance in harsh environments

At this point, I have to admit that conductive plastic products fit these targets better. With standardized dual-gang and multi-gang structures, plus modular stacking, complex needs can be split into multiple controllable units.

This is also a kind of progress.

8. Final Notes

When I look back at old multi-gang multi-control potentiometers, I don’t want to romanticize them. They were not perfect. They had clear limits of their time. But in today’s fast-moving manufacturing world, when I suddenly see two potentiometers from eras decades apart in front of me, I’m still touched by human creativity and industrial progress.

Especially the honest and direct design thinking of ALPS: when there is no “backup plan,” they try to write the user’s feeling into the physical structure itself.

By coincidence, I met two customer needs within one week. Their product eras are so far apart. In the long evolution of manufacturing and electronics, these “stage answers” are not common.

That is why they feel interesting, and why they deserve to be understood again.