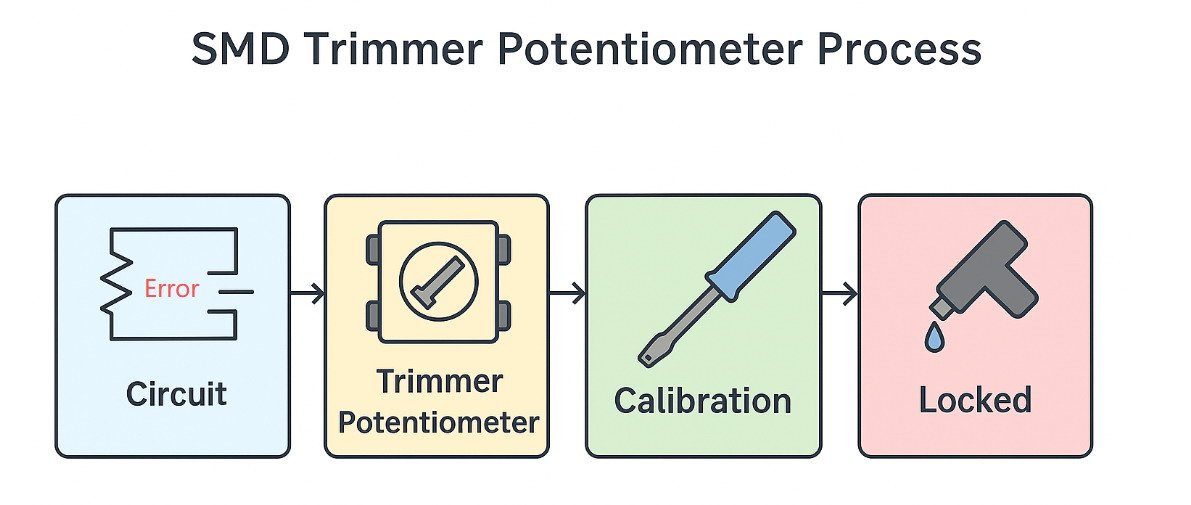

1)They are really the "adjustment screws for calibration"

SMD potentiometers may look tiny, but they are the critical “last adjustment” in circuits. They are small trimmers used to compensate the accumulated tolerances of components in a circuit—for example, fine-tuning a reference to exactly 2.500 V, or calibrating a sensor’s zero/span to spec.

- Short life: usually only a few hundred rotations, intended for one-time calibration.

- Almost always cermet: withstands reflow and offers stability.

- Locked after adjustment: typically glued or waxed after tuning.

- Single-turn vs Multi-turn = quick vs precise: single-turn is compact/fast; multi-turn offers higher resolution and better linearity.

👉 So next time you see a tiny block with a slot on a PCB, don’t mistake it for a knob—think of it like a tiny adjustment screw for calibration.

2)Origin of SMD Trimmer Potentiometers

The origin of SMD trimmer potentiometers can be traced back to 1952, when Marlan Bourns invented and patented the world’s first trimming potentiometer, branded as Trimpot®. This innovation quickly became the standard solution for fine adjustment in circuits. Interestingly, there has long been an industry story that in 1995, Bourns quietly acquired the potentiometer business of Japan’s Tocos (Tokyo Cosmos Electric) to strengthen its access to cermet (ceramic resistive track) technology. Although this acquisition was never officially documented, many engineers still see it as a turning point that accelerated the global expansion of trimmer potentiometers.

3)Why almost always cermet?

- Withstands reflow: 245–260 °C peaks don’t damage cermet; carbon film and conductive plastic degrade.

- Better stability: low TCR and humidity drift; carbon/plastic worse.

- Resistant to cleaning: cermet is inert; plastic swells.

- Laser trimming supported: improves mass production precision.

- Industry standard: cermet dominates SMD trimmers.

👉 Simply put: one-time calibration + reflow + compact size → choose cermet.

4)Typical Applications

- Power reference voltage calibration (e.g., 2.500 V fine-tuning)

- Amplifier bias adjustment

- Sensor zero/span calibration

- Audio level and filter tuning

- Factory calibration in telecom, medical, automotive boards

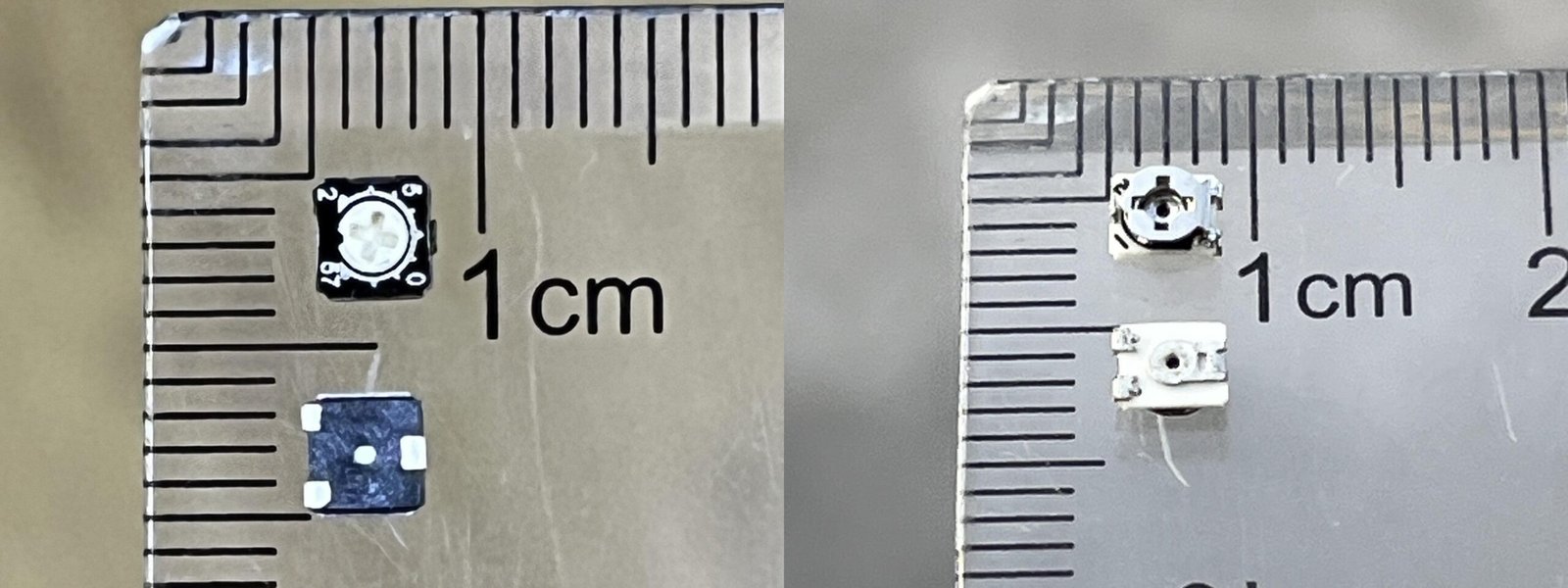

5)Single-turn vs Multi-turn

Single-turn:

- Travel ~270°–300°

- Quick adjustment, simple, compact

- Common in consumer/general industrial

Multi-turn:

- Requires 5–12+ turns

- Higher resolution, better linearity

- Larger, costlier, used in precision/automotive

Comparison Table

| Feature | Single-Turn | Multi-Turn |

|---|---|---|

| Rotation | ~270°–300° | 5–12+ turns |

| Accuracy & Resolution | Medium | High |

| Size | Compact (~3–4 mm) | Larger |

| Cost | Lower | Higher |

| Applications | Consumer/general industrial | Precision/automotive ECU |

6)NOLELC Alternatives(Single-Turn)

| Series | Turns | Size class | Typical range |

|---|---|---|---|

| COPAL ST-32 | Single | ~3–4 mm | 10 Ω – 1 MΩ |

| HDK VG039 (e.g., VG039NCHXT) | Single | ~3.7-3.9 mm | 10 Ω – 2 MΩ |

| Panasonic EVM3E (e.g., EVM3ESX) | Single | ~3.5 mm | Full range available |

| Bourns 3314J | Single | ~4.6-5.0 mm (low profile) | 10 Ω – 1 MΩ |

NOLELC already has the capability to provide alternatives to the models listed above. Our products match the originals in size, resistance range, and electrical performance, offering customers the same experience with more flexible supply options.

END