Industrial potentiometers are vital for controlling electrical parameters in systems requiring precision, such as large machinery, medical devices, and automotive components.

Industrial potentiometers are designed for use in systems where reliability and long-term performance are essential. In this article, we will examine the differences between industrial and civilian potentiometers, their components, and how they are used across various industries. Keep reading to understand the critical role they play.

1) Differences Between Industrial Potentiometers and Civilian Potentiometers?

Industrial potentiometers differ from civilian ones in terms of precision, durability, and application scope, particularly in high-stress environments.

Industrial potentiometers are built to handle extreme environments, while civilian versions are typically used in consumer products.

Key Differences

| Aspect | Industrial Potentiometers | Civilian Potentiometers |

|---|---|---|

| Durability | High resistance to environmental stress | Less durable, suitable for controlled environments |

| Precision | Designed for high precision in critical applications | Moderate precision for non-critical applications |

| Applications | Aerospace, automotive, medical, heavy machinery | Consumer electronics, audio equipment, hobby projects |

| Materials Used | Specialized materials for harsh conditions | Common materials such as plastics and low-cost metals |

| Size and Design | Larger, often custom-made for specific needs | Small, mass-produced designs for general use |

Industrial potentiometers are engineered for heavy-duty use in high-stress environments like factories and medical equipment. In contrast, civilian potentiometers are usually found in consumer electronics, offering lower durability and precision. Industrial versions can endure extreme temperatures, humidity, and mechanical stresses.

Industrial potentiometers are tailored for heavy-duty use, while civilian ones focus on cost efficiency and basic functionality.

2) Components and Material Characteristics of Potentiometers

The materials and components of a potentiometer determine its performance, especially in demanding environments.

Potentiometers use materials like metal ceramics, carbon film, and wire-wound designs, each offering specific advantages for different applications.

The components and materials of industrial potentiometers directly affect their functionality and suitability for specific applications. Potentiometers are commonly made from metal ceramics, carbon films, and wire-wound designs. Each material type has unique properties that make it ideal for certain industrial applications.

Industrial potentiometers are vital for controlling electrical parameters in systems requiring precision, such as large machinery, medical devices, and automotive components.

Industrial potentiometers control key parameters in heavy machinery, aerospace, automotive, and medical systems, offering durability and precision for demanding environments.

Industrial potentiometers are designed for use in systems where reliability and long-term performance are essential. In this article, we will examine the differences between industrial and civilian potentiometers, their components, and how they are used across various industries. Keep reading to understand the critical role they play.

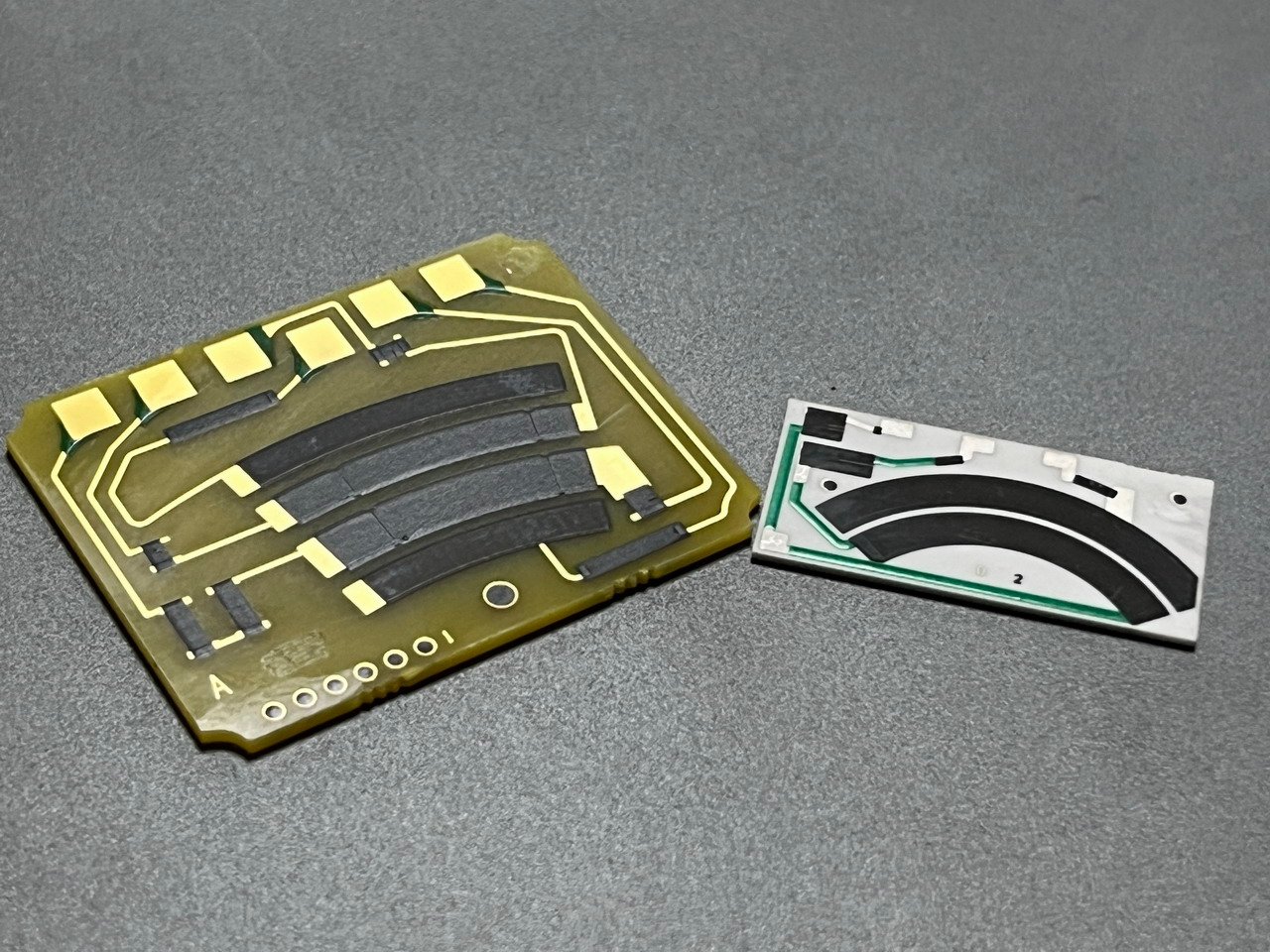

2.1 Metal Ceramic

Metal ceramic potentiometers offer exceptional thermal stability and high precision. These potentiometers are used in environments that require resistance to high temperatures and mechanical wear, such as in aerospace and automotive applications. Their durability ensures long-term functionality even under harsh conditions.

2.2 Carbon Film or Conductive Plastic

Carbon film potentiometers are widely used in industrial applications for moderate precision tasks. They are cost-effective and provide stable electrical resistance, making them a great option for non-critical systems. Conductive plastic potentiometers, while similar, provide smoother operation and better durability, ideal for automation.

2.3 Wire-Wound

Wire-wound potentiometers offer the highest precision and can handle higher power ratings compared to other types. The resistance element is created by winding a fine wire around a core, providing excellent accuracy and performance. These are ideal for scientific instruments and applications that demand precise control.

2.4 Characteristics List

| Component Type | Advantages | Common Uses |

|---|---|---|

| Metal Ceramic | High thermal stability, durability, precision | Aerospace, automotive, medical |

| Conductive Plastic-Carbon Film | Smooth movement, low noise, durability Cost-effective, stable resistance | Industrial automation, robotics and consumer uses |

| Wire-Wound | High precision, can handle higher power loads | Precision instruments, scientific applications |

The choice of materials plays a key role in determining the potentiometer’s suitability for an application, balancing cost, precision, and durability.

3) Industrial Potentiometer Processes and Features

The manufacturing process of industrial potentiometers ensures that they perform reliably in demanding environments.

Industrial potentiometers are manufactured with precision processes that ensure high performance, durability, and reliability for critical systems.

Manufacturing processes for industrial potentiometers are designed to ensure the highest quality and reliability. These processes include precision machining, environmental testing, and stringent quality control. The goal is to create potentiometers that can withstand the harsh conditions they will be exposed to in industrial settings.

3.1 Performance comparison

| Process | Carbon Film Potentiometer | Metal Ceramic Potentiometer | Wire Wound Potentiometer |

|---|---|---|---|

| Precision | Standard | High | Very High |

| Temperature Tolerance | Low | High | High |

| Durability | Standard | High | Very High |

| Cost | Low | Medium | High |

3.2 Characteristics of Resistor Element Materials

| Carbon Film Potentiometer | Metal Ceramic Potentiometer | Wire Wound Potentiometer | |

|---|---|---|---|

| Raw materials | Cermet combines ceramic with precious metals | plastic resin and carbon powder | Look at the name above |

| Laser Trimmed Accuracy | Yes | Yes | No |

| Linearity | < 0.05 % | < 0.25 % | < 0.1 % |

| Temperature Coefficient | 500 ppm/°C | 100 ppm/°C | 50 ppm/°C |

| noise | Best | Low Noise | Low static noise |

| Life | Longest | Standard | Long |

3.3 Focus on temperature drift:

- Temperature drift is a comprehensive parameter. Although there is a test value, it is actually most relevant to Carbon (Conductive Plastic) Potentiometers.

- Factories cannot absolutely control it during the processing. This process involves multiple controls from materials to the processing stage, rather than simply relying on improving a single aspect to ensure the temperature drift value.

- Most industrial-grade requirements for temperature drift are less than 500 ppm, with many actually requiring below 300 ppm.

- Industrial products with high requirements for temperature drift may ultimately involve continuously testing and selecting products that meet the standards from a batch. Therefore, the yield rate, along with materials and processing methods, collectively determines the cost.

The processing method plays a crucial role in determining the final performance characteristics of the potentiometer. Each type undergoes specific manufacturing steps that enhance its suitability for different industrial needs.

3.4 Importance of Factory Test Reports

Factory test reports are essential in ensuring the quality and reliability of industrial potentiometers. These reports measure key parameters such as resistance tolerance, temperature stability, and mechanical wear. The yield rate, which indicates the proportion of potentiometers meeting quality standards, is also an important factor. Low yield rates can signal production issues, leading to higher failure rates in critical systems.

4) Application Range of Industrial Potentiometers

Industrial potentiometers are crucial for many applications in fields like automotive, manufacturing, and renewable energy. Their ability to provide precise control makes them indispensable for optimizing performance in these systems.

4.1 Throttle Position Acceleration Sensor

Throttle position sensors in automotive applications rely on industrial potentiometers to measure the position of the throttle. These sensors help regulate engine performance, optimize fuel efficiency, and reduce emissions, making them essential for modern vehicles.

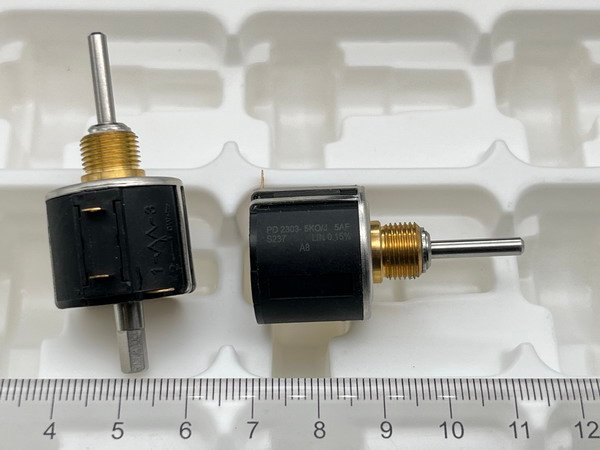

4.2 Roland 700 printing press

Contelec-PD2303 PD2310

In industrial printing systems, such as those manufactured by Manroland, potentiometers are used to control print head positions and paper feeding. Precise control ensures high-quality printing and minimizes wear and tear on the machinery.

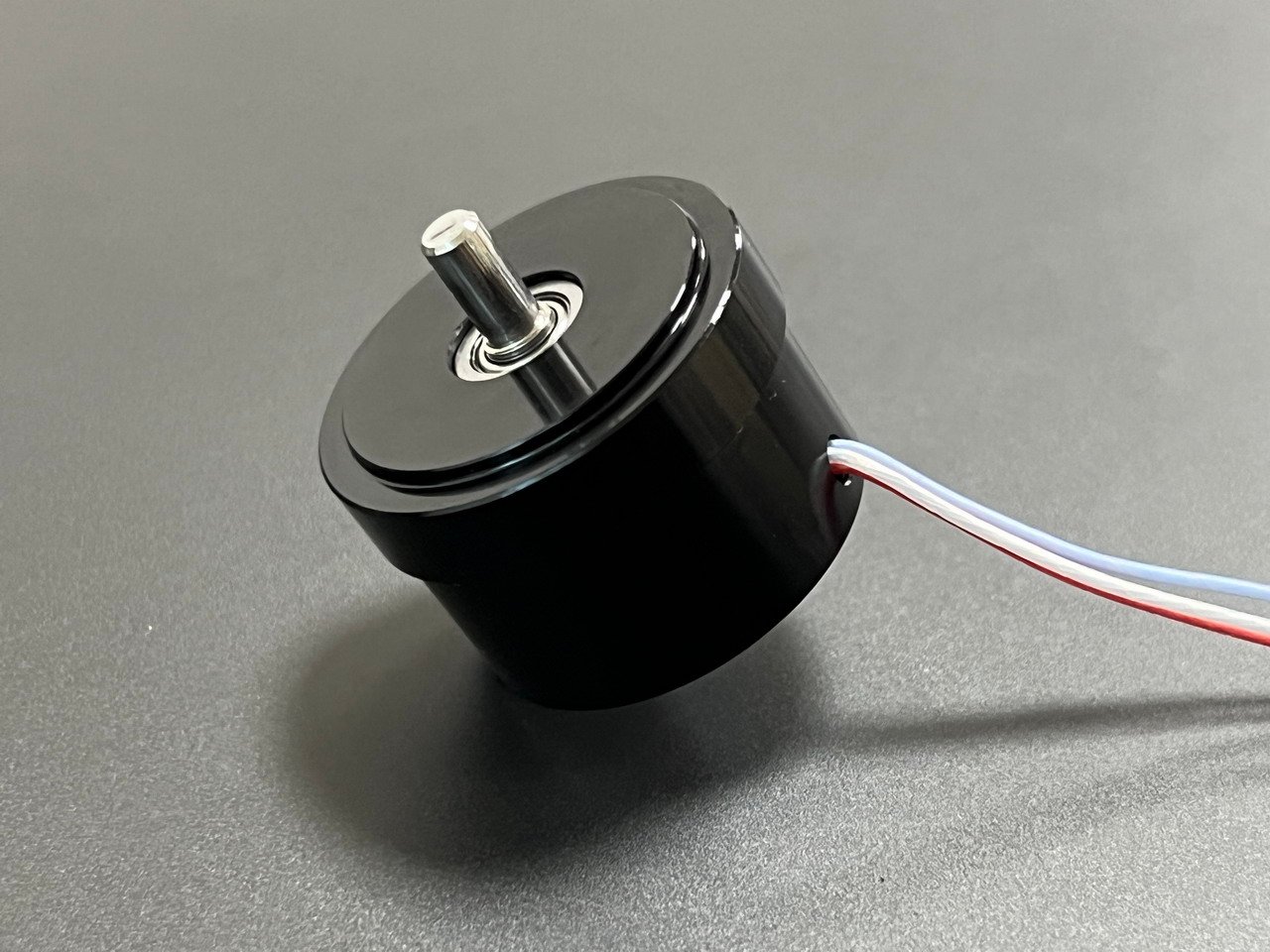

4.3 NRG Wind Sensor

NRG 40C

NRG Systems use potentiometers in their wind speed and direction sensors to monitor wind conditions for renewable energy applications. The potentiometers help measure subtle changes in wind direction and speed, providing critical data for wind turbine operations.

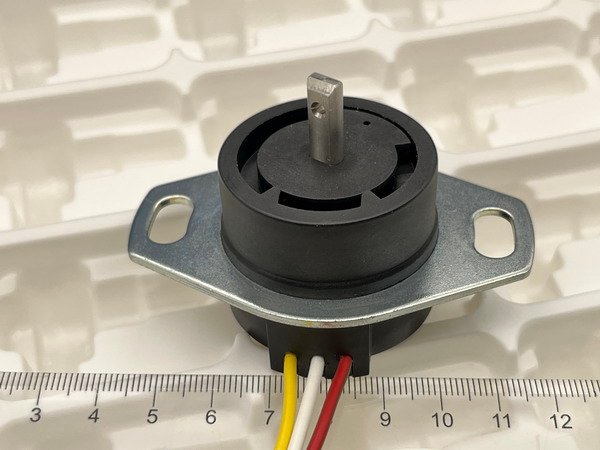

4.4 Caterpillar Forklift Throttle Position Sensor

TOCOS-PS05L5 Angle Senso for Caterpillar Forklift

Forklifts, particularly those from Caterpillar, use potentiometers to monitor throttle positions. Accurate readings ensure smooth operation, better control over speed, and improve safety in material handling operations.

5) Conclusion

Industrial potentiometers are essential for high-precision applications across various industries, including automotive, aerospace, and medical fields. Their durability, precision, and customizability make them indispensable in demanding systems.