Overview of Angle Sensors

Angle sensors convert mechanical rotation into electrical signals, enabling accurate position feedback. They include potentiometers, rotary encoders, and contactless sensors, each with unique features.

Understanding different types of angle sensors helps in selecting the most suitable one for your needs.

Precision potentiometers, absolute encoders, and rotary encoders—offered in both single-turn and multi-turn varieties—provide industrial-grade performance with substantially tighter electrical and mechanical tolerances, longer service life, and higher reliability than standard low-cost potentiometers. Available in wire-wound or conductive plastic versions, they feature options such as bushing mounts (sleeve bearings), servo mounts (ball bearings), hollow shafts, and numerous electrical and mechanical configurations.

Absolute encoders measure rotational position, convert it into electrical signals, and output absolute values. They typically rely on magnetic Hall-effect sensor technology, ensuring a contactless measuring principle and virtually unlimited sensor lifespan. With multiple electrical outputs, connection methods, and mechanical layouts, they deliver reproducible and precise data for a wide range of applications. Single-turn models handle angles up to 360 degrees, while multi-turn types exceed that range. They can also be programmed to meet specific output requirements.

Incremental encoders specialize in accurately detecting high rotational speeds or angular velocities. By generating pulse signals read by external counters or evaluation units, they enable precise measurement. Utilizing contactless methods such as opto-electronic or magnetic (Hall-effect) technology, these encoders come in a variety of connection and mechanical designs to suit different operational needs.

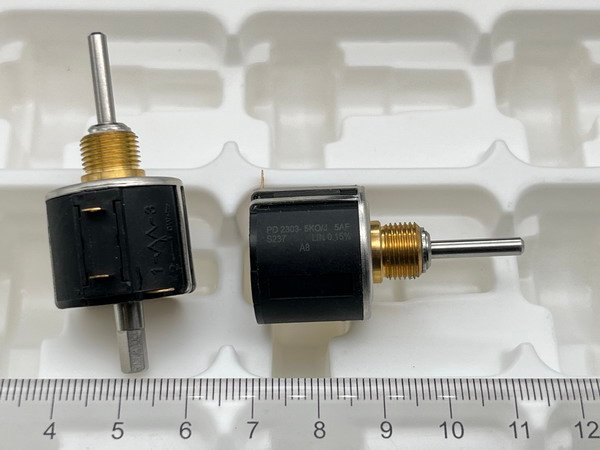

1) Precision Potentiometers

Precision potentiometers offer accurate rotational measurement through resistive elements and mechanical wipers.

These potentiometers provide high precision and repeatability but involve mechanical contact, which can affect durability over time.

By utilizing conductive plastic and wire-wound materials as resistor elements, these industrial-grade potentiometers deliver notably higher electrical and mechanical precision, a longer operational lifespan, and enhanced reliability—far surpassing typical low-cost models in component quality.

They are available in a broad range of sizes and measurement angles to meet diverse application needs. Mounting options include bushing (panel) mounts, servo mounts with ball bearings, and hollow shafts (through-shaft). Owing to their high accuracy, these sensors are employed extensively across industrial automation, mobile machinery, medical equipment, control panels, robotics, and countless other applications demanding precise input or feedback.

Features and Common Applications

| Type | Key Features | Common Applications |

|---|---|---|

| Single Turn Conductive Plastic | High linearity, low friction, long life | Industrial automation, medical devices |

| Single Turn Wire-Wound | High accuracy, robust, suitable for harsh environments | Aerospace, precision control |

| Bushing Mount (Sleeve Bearing) | Cost-effective, reliable, compact | Moderate-precision applications |

| Servo Mount (Ball Bearings) | Low friction, high durability, smooth movement | Aerospace, industrial automation |

| Hollow Shaft (Through Shaft) | Direct shaft mounting, eliminates coupling errors | Robotics, motion control |

| IP65 Protection Grade (Sealed) | Dust and moisture protection, long lifespan | Outdoor, industrial environments |

2) Precision Contactless Potentiometers

These sensors use magnetic or inductive principles to provide precise angle measurement without physical contact, making them ideal for harsh environments and long-life applications.

Magnetic rotary encoders facilitate absolute angle detection, while Hall-effect and inductive sensors (often referred to as contactless potentiometers) are increasingly supplanting traditional “sliding wiper” wire-wound or conductive plastic potentiometers. By leveraging software alongside advanced semiconductor technology, these modern encoders achieve low noise and high-precision measurements for any angle up to 360°.

They excel in position control feedback tasks and in scenarios requiring the conversion of rotary motion into an analog electrical output. These devices are commonly integrated into heavy machinery, medical systems, marine equipment, mobile machinery, and a host of other industrial environments.

Features and Common Applications

| Type | Key Features | Common Applications |

|---|---|---|

| Single Turn Hall Effect | Magnetic-based, high accuracy, long lifespan | Automotive, robotics |

| Single Turn Inductive | No contact, resistant to interference | Aerospace, automation |

3) Precision Multi-Turn Potentiometers

Multi-turn potentiometers are designed for applications requiring continuous rotation measurement over multiple revolutions.

These sensors provide high accuracy in extended-range angle measurement, making them ideal for robotics, automation, and valve control.

There are three primary operating principles: conductive plastic, wire-wound, and Hall-effect (magnetic).

Among multi-turn potentiometers, wire-wound and hybrid options are common, typically offered in 3, 5, or 10-turn variants, while wire-wound technology alone extends to 15-turn and 20-turn units. Meanwhile, field-programmable magnetic multi-turn encoders can handle up to 200 turns (72,000°) at a 12-bit resolution per turn, with available analog outputs of 0–5V, 0–10V, or 4–20mA.

Designed to endure the rigors of varied industrial applications, these multi-turn sensors and encoders feature robust construction and multiple mounting styles—bushing (sleeve bearing), servo mount (ball bearings), and hollow shaft—ensuring flexibility and reliability across a range of use cases.

Features and Common Applications

| Type | Key Features | Common Applications |

|---|---|---|

| Multi-Turn Wire-Wound | High durability, precise positioning | Industrial machinery |

| Multi-Turn Hybrid | Combines wire-wound and conductive plastic benefits | Medical devices, automation |

| Multi-Turn Hall Effect Contactless | No mechanical wear, high precision | Aerospace, robotics |

| Multi-Turn Programmable Encoders | Customizable, digital output | Robotics, CNC |

| Turns Counting Dials | Displays rotation count for easy reference | Manual adjustment systems |

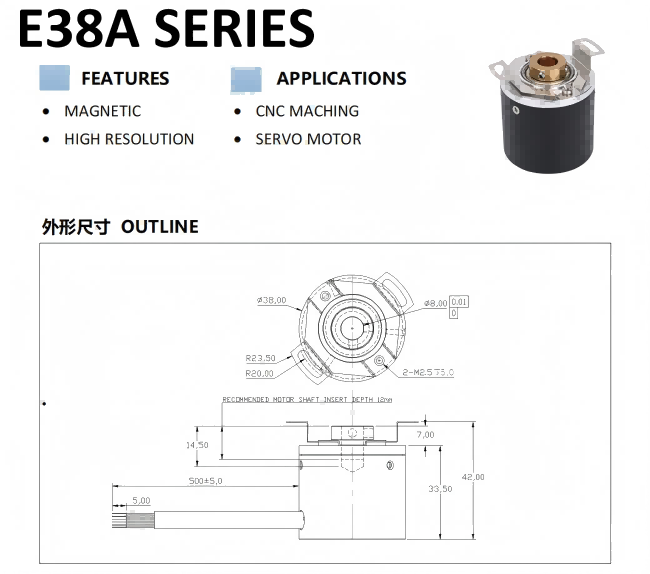

4) Rotary Encoders - Absolute

Absolute rotary encodersprovide unique position data that remains unchanged even after power loss.

These encoders generate distinct digital signals for each angular position, ensuring precise and repeatable positioning in automation and robotics.

Absolute rotary encoders offer a broad range of solutions for numerous applications. They measure velocity, direction of movement, or the angular position of a rotating shaft, making them an excellent choice for scenarios that demand precise and reliable motion tracking.

Features and Common Applications

| Type | Key Features | Common Applications |

|---|---|---|

| Analog Output - Hall Effect | Continuous voltage output, smooth control | Industrial automation |

| Serial (SER/SSI/SPI) Output - Hall Effect | Digital communication, high precision | Robotics, medical devices |

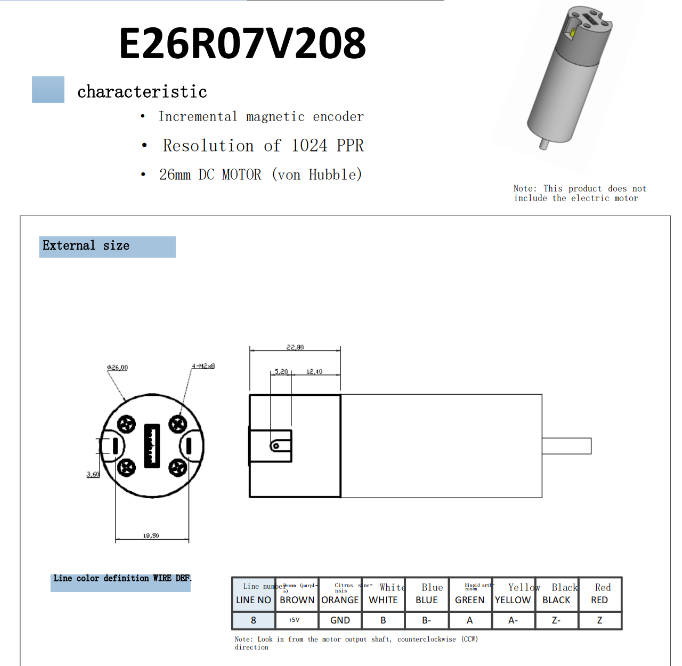

5) Rotary Encoders - Incremental

They do not retain position after power loss and require a reference point but are ideal for high-speed motion tracking.

Incremental encoders produce a digital output signal whenever the shaft rotates, making them indispensable for delivering position, direction, and speed data within motion control systems across diverse industries. From aerospace and defense to consumer electronics and industrial automation, these sensors are widely utilized in numerous applications.

They come in various mounting configurations, with resolutions ranging from 50 PPR to 16,000 PPR, offered in both optical and Hall-effect designs.

Features and Common Applications

| Type | Key Features | Common Applications |

|---|---|---|

| Incremental Encoders - Hall Effect | Magnetic sensing, accurate speed tracking | Motor control, automation |

| Incremental Encoders - Optical | High resolution, precise motion feedback | CNC, aerospace |

6) Conclusion

Choosing the right angle sensor depends on precision, durability, and application needs. From potentiometers to rotary encoders, each type serves specific industrial and automation requirements.