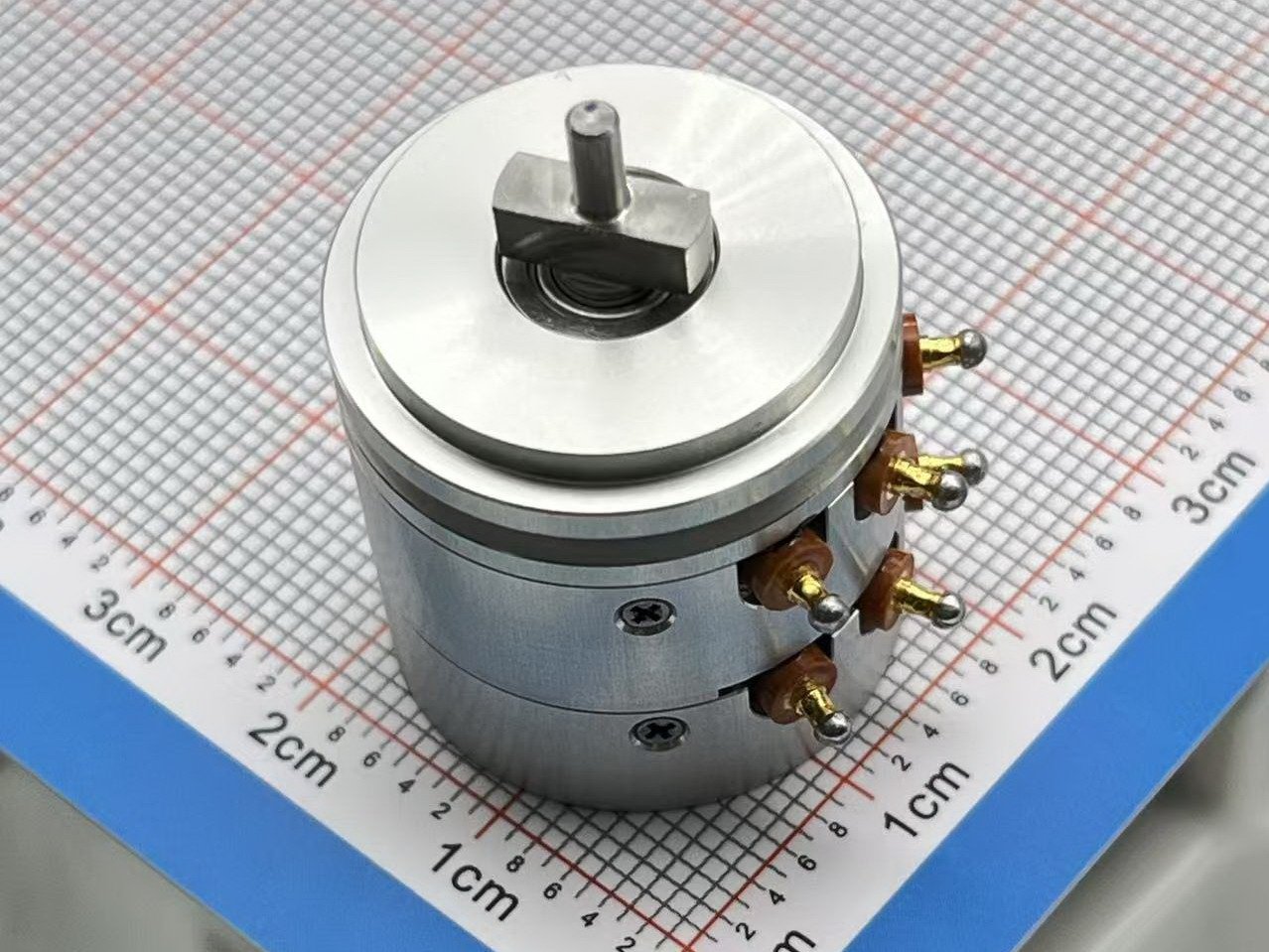

Dual-channel redundant conductive-plastic rotary potentiometer/angle sensor for aircraft: two stacked, independent tracks and wipers provide redundant outputs—if one channel fails, the other continues delivering position feedback. The aluminum body and D-shaft allow secure mounting, while gold-plated terminals improve conductivity and corrosion resistance, ideal for long-term, safety-critical position sensing.

A conductive plastic potentiometer is a high-precision variable resistor that uses conductive plastic as the resistive element. It operates by moving a wiper along the conductive plastic track, changing the output voltage to measure or control position, angle, or displacement with high accuracy.

1. Origin of Conductive Plastic Resistive Elements

The development of conductive plastic potentiometers originated from the demand for higher precision and longer service life. In the 1950s and 1960s, as aerospace and precision instrumentation advanced, traditional wire-wound potentiometers revealed limitations such as low resolution, high noise, and rapid wear.

By dispersing carbon black or metallic particles uniformly within a polymer binder to form a continuous conductive film, conductive plastic elements solved these issues. Combining the smooth response of carbon film with the durability of wire-wound designs, they became a major innovation in precision control systems.

2. Why Conductive Plastic Potentiometers Emerged

While wire-wound potentiometers were reliable, their resolution was limited by winding pitch. Carbon film versions, though inexpensive, suffered from short lifespan, drift, and noise.

Conductive plastic potentiometers, using continuous resistive films, deliver smooth output and significantly improved wear resistance and stability. Their performance sits between carbon film and wire-wound types, making them ideal for automation and instrumentation systems.

This military-grade conductive plastic resistive element features an annular resistive track made of high-temperature-cured conductive plastic. It maintains excellent linearity and resistance stability across extreme environments from -70 °C to +125 °C. The three-lead configuration allows easy integration and testing, ideal for aerospace, motor feedback, and precision angle-sensing applications.(6915-1002-030)

3. Applications and Market Evolution

Since its invention, the conductive plastic potentiometer has continuously expanded in application:

- 1960s–1970s: Used mainly in precision instruments and military control systems.

- 1980s–1990s: Adopted widely in industrial automation and servo mechanisms.

- 2000s onward: Extensively implemented in automotive throttle, steering, and brake sensors.

- Current trends: Although some high-end systems now favor non-contact designs, conductive plastic potentiometers remain mainstream for mid-to-high precision due to cost-effectiveness and integration simplicity.

4. Typical Performance Range of Conductive Plastic Potentiometers

| Parameter | Rotary Type | Linear Type |

|---|---|---|

| Electrical Travel | 240°–350° (up to 360° available) | 10–300 mm (customizable longer range) |

| Linearity | ±0.3%–±1.0%, high-precision models up to ±0.15% | ±0.1%–±0.5%, economy models around ±1.0% |

| Resolution | Practically continuous (no discrete steps) | Same as left |

| Life (Electrical/Mechanical) | 10⁵–10⁶ turns; premium models reach several million turns | Several million to tens of millions of strokes |

| Operating Temperature | −40 °C to +85 °C; automotive/industrial grade up to +125 °C | Same as left |

| TCR / Drift | ±150–500 ppm/°C typical | Same as left |

| Power Rating | 0.25–2 W depending on size and resistance | Tens to hundreds of mW |

| Sealing | Open type to IP67 depending on model | Same as left |

Rotary types are often used for angular control and knob adjustment, while linear types are suited for displacement or feedback sensing. Actual accuracy depends on temperature, power stability, and mechanical assembly precision.

5. Advantages (Conservative Overview)

- Continuous Output — Smooth signal without wire-step effects.

- Good Linearity — Typical ±0.3%–±1%, suitable for precision feedback.

- Low Noise — Stable wiper contact produces clean analog output.

- Long Service Life — Capable of millions of cycles under proper sealing and moderate load.

- Fast Response — Immediate analog response without latency.

- Customizable Design — Resistance value, stroke, geometry, and taper can all be tailored.

6. Limitations and Drawbacks

- Environmental Sensitivity — Performance may degrade in high humidity, dust, or oily environments.

- Limited Power Handling — Plastic films have limited thermal stability, unsuitable for high-load circuits.

- Contact Wear — Repeated motion and side force can wear the wiper contact.

- Higher Cost — Materials and manufacturing require higher precision and stricter inspection processes.

7. Summary

The conductive plastic potentiometer achieves a practical balance among resolution, linearity, and lifespan. Rather than chasing theoretical limits, it focuses on long-term reliability and smooth output.

Across industrial, automotive, medical, and aerospace applications, it remains one of the most stable and cost-effective contact-type sensing solutions.

With ongoing material and thick-film advancements, its scope of application continues to expand steadily.