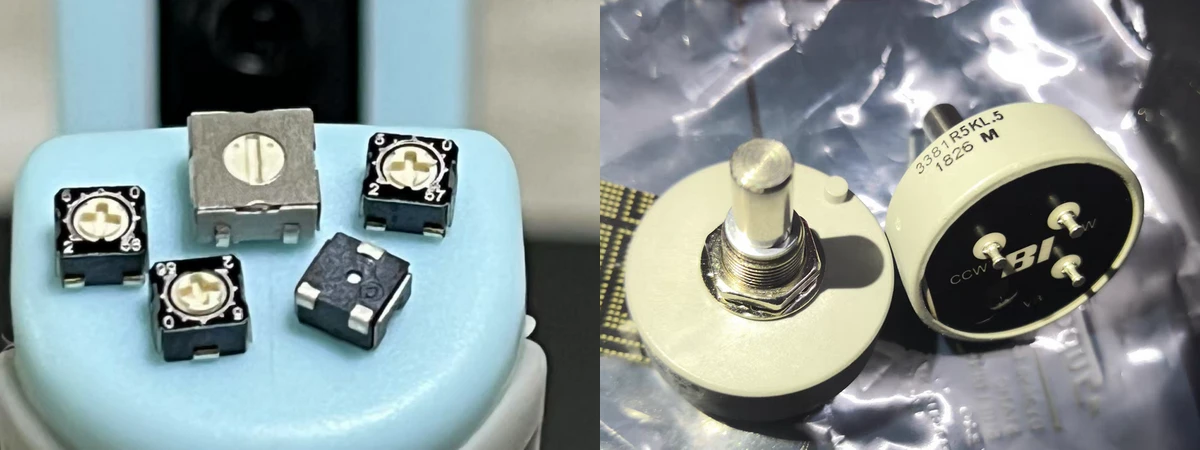

The left side shows mainstream SMD single-turn trimmers—Bourns 3314J, Panasonic EVM3E, and Copal ST-32—commonly used in SMT production for one-time factory calibration.

Summary

SMD trimmer potentiometers (e.g., 3314) and multi-turn trimmer potentiometers (e.g., 3381/3296/3386) serve the same purpose: fine resistance adjustment. The split is how and how often you trim.

SMD favors one-time factory set-and-lock in compact SMT flows, while multi-turn types enable repeatable, ultra-fine calibration with better serviceability.

Each spans a different kind of “breadth”: SMD across the manufacturing ecosystem, multi-turn across the precision-calibration ecosystem.

1) What they are

- SMD trimmers (mostly single-turn): Surface-mount, top/side adjust, low profile, reflow-compatible; ideal for one-time production trims.

- Multi-turn trimmers (10–25 turns): Mainly THT with lead-screw/gear mechanisms; high resolution and repeatable; ideal for precision calibration and service.

2) Construction & process

SMD is compact with short travel and fits SMT + reflow (fast takt, lower BOM/manufacturing cost).

Multi-turn is larger with fine travel; typically wave/hand soldered and friendlier to end-of-line or field trims.

3) Performance focus

- Resolution: Single-turn SMD targets an acceptable window; multi-turn lets you land precisely.

- Power: SMD ~0.05–0.25 W (@70 °C); multi-turn ~0.25–0.5 W (series-dependent).

- Vibration / reliability: SMD’s low profile helps; multi-turn should be adhesive-locked or sealed for stability and moisture protection.

4) Where they’re actually used

SMD fits (one-time trim / compact / full SMT):

- One-time factory trim then lock with adhesive/conformal coating.

- Consumer, wearables, compact PSUs, dense digital boards where space and throughput dominate.

Multi-turn fits (repeatable calibration / ultra-fine granularity):

- Instruments & bridges: zero/span trims with repeatable setpoint return.

- Precision analog: op-amp offset/bias, reference dividers, filter bandwidth.

- Industrial control: servo zero, PID seeds, relay trips, PSU Vout/ILIM.

- Medical/aerospace: periodic recalibration with strict records.

- Audio/low-freq analog: channel balance, level matching, long-term bias stability.

Takeaway: SMD spans the broader manufacturing front; multi-turn spans the deeper precision-calibration front.

5) Quick spec snapshot

| Dimension | SMD trimmers (e.g., 3314) | Multi-turn trimmers (e.g., 3381/3296) |

|---|---|---|

| Mounting | SMD, reflow | THT, wave/hand |

| Turns | Single-turn (short travel) | 10–25 turns (lead-screw/gear) |

| Typical power | 0.05–0.25 W | 0.25–0.5 W |

| Profile | Low, compact | Taller, larger |

| Adjustment frequency | One-time set | Repeatable fine trims |

| Vibration | Low-profile advantage | Stable when locked/sealed |

| Service | Rarely touched after set | Easy to recalibrate/service |

Note: Values are typical ranges; always verify against target datasheets.

6) Quick Selection

| Topic | Guidance |

|---|---|

| Process path | Full-SMT and tight space → pick SMD trimmer |

| Trim pattern | One-time set & lock → SMD; need >10 turns with repeatable fine trims → multi-turn |

| Power & environment | Low–mid power, dense layout → SMD; higher headroom/thermal stability or higher ambient → multi-turn (lock/seal after trim) |

| Vibration & service | High vibration/shock → SMD; if multi-turn is required → adhesive/conformal coat and sealed versions for serviceability |

| One-liner | Throughput/compact → SMD; repeatable ultra-fine calibration/serviceability → multi-turn |

7) Taxonomy (for internal links)

By mounting

- SMD trimmers (single-turn): 3314J (top-adjust, 3×3 mm), 3314G (side-adjust, 3×3 mm), TC33 (top-adjust, 3×3 mm), SM-42 (7×7 mm low-profile)

- THT trimmers (single-turn): 3362 (top/side-adjust), 3386 (vertical/horizontal)

- THT trimmers (multi-turn): 3381 (lead-screw, 10–25 turns), 3296 (sealed multi-turn)

Typical footprints

- SMD:

- ~3–4 mm (e.g., COPAL ST-32)

- ~3.7–3.9 mm (e.g., HDK VG039 / VG039NCHXT)

- ~3.5 mm (e.g., Panasonic EVM3E / EVM3ESX)

- ~4.6–5.0 mm, low profile (e.g., Bourns 3314J)

- 7×7 mm (e.g., SM-42 low-profile)

- THT: vertical (lead pitch 2.5–5.0 mm), horizontal (lead pitch 2.5–5.0 mm)