Servo potentiometers are core components in industrial automation, aerospace, and robotics, renowned for precision and reliability. From reducing robot maintenance costs to enhancing CNC machine efficiency, they are indispensable in modern precision control. This article explores their origins, materials, functions, precision, and future trends, offering practical insights for procurement engineers.

1) Why Did Servo Potentiometers Emerge?

The history of servo potentiometers dates back to early 20th-century servomechanisms, initially used in military fire-control systems and marine navigation. Records show servo systems first appeared in 1908 for cannon aiming, requiring mechanical feedback for precision [Wikipedia Servomechanism]. Servo potentiometers, as analog feedback components, gained prominence in the 1940s in aerospace, such as in aircraft autopilots. By the 1960s, with the rise of industrial automation, they were adopted in CNC machines and early robotics to meet precise position and angle control needs [P3 America].

2) Main Materials Used in Servo Potentiometers

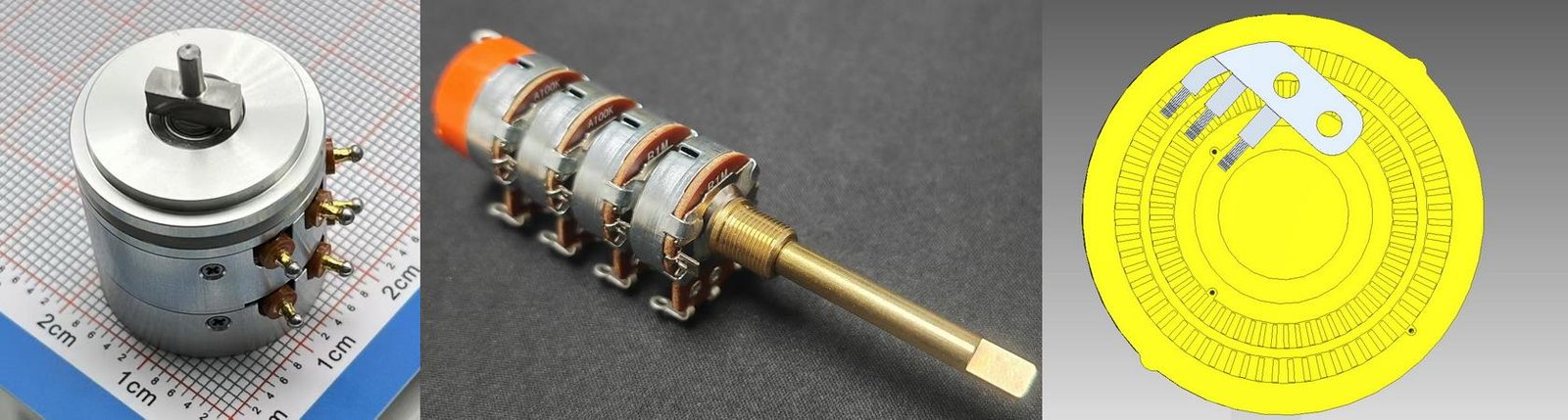

The performance of servo potentiometers relies on their materials. The resistive element typically uses:

- Conductive Plastic: Made from polymer substrates doped with conductive particles, offering low noise, high smoothness, and excellent resolution for high-precision applications. Its manufacturing involves precision molding to ensure uniform resistance [Omega Engineering].

- Wirewound Materials: Created by winding nickel-chromium alloy wires around a ceramic or plastic core, providing superior durability and temperature stability but slightly lower resolution [Potentiometer Wikipedia].

The wiper (sliding contact) is usually made of carbon-based composites or precious metal alloys (e.g., gold or silver). Carbon wipers are cost-effective for general use, while precious metal wipers offer lower contact resistance and longer life, often used in aerospace [Servo Instrument]. For instance, some servo potentiometers use multi-finger precious metal wipers, achieving a 50-million-cycle lifespan. The bearing system (e.g., ball bearings) ensures smooth wiper movement and minimal wear.

3) Main Functions of Servo Potentiometers

Servo potentiometers enable precise position feedback via variable resistance. Key applications include:

- Automatic Steering Systems: In automotive and marine autopilots, they monitor steering angles for accurate navigation [P3 America].

- Industrial Robotics: They provide ±0.5° accuracy for six-axis robot joints. For example, an automation factory improved robot efficiency by 15% and reduced downtime using optimized servo potentiometers.

- Drone Gimbals: They stabilize camera positions against wind, ensuring high-quality footage.

These applications benefit from the fast response and reliability of servo potentiometers.

4) Precision and Control Force of Servo Potentiometers

Servo potentiometer precision is measured by linearity, with high-precision models achieving ±0.05% to ±0.1% and a temperature coefficient of 80 ppm/°C, stable from -55°C to 125°C [Servo Instrument]. Below is a performance comparison of common materials:

| Material | Linearity | Lifespan (Cycles) | Temp. Coefficient | Applications |

|---|---|---|---|---|

| Conductive Plastic | ±0.05% | 50M | 80 ppm/°C | Robotics, Aerospace |

| Wirewound | ±0.1% | 100M | 50 ppm/°C | CNC Machines, Industrial Control |

Control force (0.01-0.1 Nm) is provided by servo motors, with ball bearings and multi-finger wipers reducing friction. Precision testing uses laser interferometers for micrometer-level accuracy [Omega Engineering].

5) Future Development Directions of Servo Potentiometers

The future of servo potentiometers will focus on:

- Higher Precision: Laser trimming of resistive elements could achieve linearity of ±0.01% [P3 America].

- Longer Lifespan: Carbon nanotube or graphene-based coatings could enhance wear resistance, exceeding 100 million cycles [Emerging Materials].

- Greater Durability: Potentiometers resistant to extreme temperatures (-70°C to 150°C) and vibrations for aerospace applications.

- Miniaturization: Miniature potentiometers will support medical robots and wearables.

While digital encoders gain traction for contactless design, analog servo potentiometers remain competitive in cost-sensitive applications. Hybrid solutions (analog + digital) will enhance performance.

References

- [Servo Instrument]: Servo Instrument Corporation, “Precision Potentiometers,” http://www.servoinstrument.com/precision_potentiometer.htm

- [Wikipedia Servomechanism]: Wikipedia, “Servomechanism,” https://en.wikipedia.org/wiki/Servomechanism

- [P3 America]: P3 America, “Servo Mount Potentiometers with Ball Bearings,” https://p3america.com/angle-sensors/precision-potentiometers/servo-mount-ball-bearings/

- [Omega Engineering]: Omega Engineering, “Servo Potentiometers,” https://www.omeg.co.uk/builder/servos/

- [Potentiometer Wikipedia]: Wikipedia, “Potentiometer,” https://en.wikipedia.org/wiki/Potentiometer

- [Emerging Materials]: (Placeholder for emerging material trends, based on industry insights; specific source TBD)