One thing I’ve always disliked is when someone shows me a product with a beautiful outer casing and says, “This is a good one.”

But whenever I asked about detailed specifications or real applications, the conversation usually ended there.

That’s when I realized — what truly deserves attention isn’t the casing, but the structure, materials, and principles inside.

The shell represents protection and lifespan, while performance lives within the inside.

It’s like comparing Stephen Hawking with a professional athlete — different forms of strength, both equally admirable.

1. What Is a Servo Potentiometer?

A servo potentiometer (often referred to simply as a servo pot) is a high-precision position-sensing component used in closed-loop control systems. It converts rotational or linear displacement into proportional electrical signals, enabling accurate motion feedback. In a servo system, it acts as the “position awareness” element and is widely used in aerospace control, robotic joints, industrial automation, and medical equipment.

2. Core Component #1 — Resistive Element

The resistive element forms the foundation of any servo potentiometer. Its material defines the resolution, linearity, signal stability, and lifetime of the device.

Common materials include:

- Conductive plastic

- Carbon film

- Cermet (ceramic–metal)

- Wire-wound designs

As precision and durability requirements increase, conductive plastic films have become the dominant choice for servo potentiometers.

2.1 Why Conductive Plastic Film Dominates

-

Continuous Surface and Virtually Infinite Resolution

Conductive plastic provides a smooth, uniform resistive path without the discrete steps of wire-wound types, achieving virtually infinite electrical resolution and very smooth output. -

Low Noise and Long Life

Its homogeneous conductive matrix minimizes micro-arcing and contact noise during wiper motion. The self-lubricating polymer base often exceeds 50 million rotational cycles in typical servo applications. -

Excellent Temperature Stability

The typical temperature coefficient (TCR) is below ±400 ppm/°C, ensuring stable output from –70 °C to +125 °C.

For special applications, the conductive plastic formulation and process can be further customized to achieve a TCR as low as 150–200 ppm/°C, though this significantly increases production costs. -

Customizable Resistance Laws and Linearity

The resistive track can be laser-trimmed to linear, logarithmic, or tailored response curves, which is essential for precise feedback control.

In addition, the linearity of the conductive plastic element can be fine-tuned through laser trimming and geometric design — from a standard ±0.5% to as high as ±0.15% — to meet the specific feedback accuracy required by different control systems. -

Excellent Match with Multi-wire Wipers

The smooth, wear-resistant surface supports multi-contact wipers, providing redundant signal paths and minimizing dropout in safety-critical servo systems.

2.2 Lead Wires

The signal terminals of conductive plastic elements are typically extended through solder pads or pins to lead wires.

These leads are often:

- Silver-plated high-temperature wires, or

- PTFE-insulated wires

This ensures low impedance and high reliability over a wide temperature range and establishes a stable electrical path between the resistive element and the external circuitry.

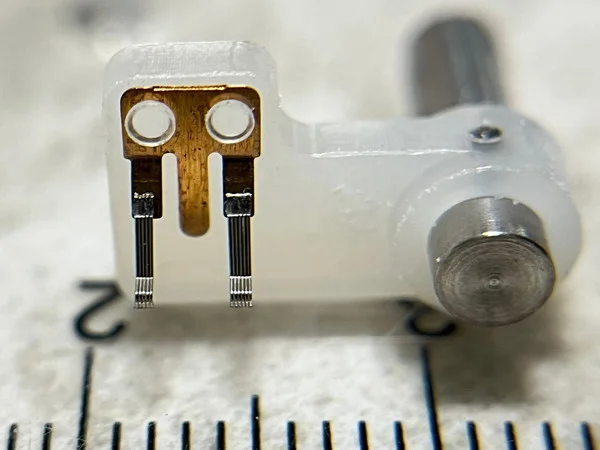

3. Core Component #2 — Wiper Assembly

The wiper is the key component that collects and transmits signals from the resistive track. It moves across the resistive surface to generate an output voltage proportional to the rotation angle. The wiper’s design, contact geometry, and material have a direct impact on accuracy, noise, and lifetime.

3.1 Wiper Types and Design

-

Single-wire wiper

A basic design suitable for standard feedback applications where redundancy is not required. -

Dual-wire wiper

Reduces contact noise and improves signal stability by providing two parallel contact paths. -

Multi-wire wiper

Each contact provides an independent path, adding redundancy and fault tolerance.

This type is widely used in aerospace, robotics, and military servo systems where loss of feedback is unacceptable.

3.2 Wiper Materials and Bracket Design

Servo potentiometer wipers are typically made of precious-metal alloys such as silver, rhodium, or platinum, sometimes with gold plating. These materials ensure stable contact resistance at low contact pressure, reducing both mechanical wear and electrical noise.

The wiper bracket is usually made of:

- Beryllium copper (BeCu), or

- Brass

Both materials offer a combination of elasticity and conductivity, allowing the wiper to maintain consistent contact pressure over long-term operation.

4. Mechanical Precision and Electrical Feedback

The mechanical assembly — bearings, slip rings, housing, and shaft — defines rotational damping and return accuracy. Tighter mechanical tolerances lead to:

- Better voltage repeatability

- Improved linearity

- More stable zero and end-point positions

Electrically, resolution and smoothness are key performance indicators.

Conductive plastic elements deliver continuous, jitter-free signals, which helps to maintain loop stability in precision servo control.

5. Material and Performance Comparison

The table below summarizes the differences among common resistive materials in terms of resolution, temperature stability, lifetime, and noise performance. Conductive plastic offers the most balanced characteristics, making it the preferred choice for servo potentiometers.

| Material Type | Resolution | TCR (Temperature Coefficient) | Life Cycles | Noise Level | Remarks |

|---|---|---|---|---|---|

| Conductive Plastic | Infinite | ±400 ppm/°C, customizable to 150–200 ppm/°C | > 50 million | Very Low | Linearity up to ±0.15%, ideal for high-precision servos |

| Carbon Film | Limited | ±1000 ppm/°C | ~ 1 million | High | Low cost, suitable for general adjustment applications |

| Cermet (Ceramic–Metal) | Medium | ±600 ppm/°C | ~ 5 million | Medium | Good stability, slightly higher cost |

| Wire-wound | Discrete steps | ±200 ppm/°C | > 10 million | Low (but not smooth) | High precision, non-continuous output |

6. Applications and Customization in Servo Systems

In servo systems, the potentiometer serves as the sensing core of the feedback loop, converting mechanical motion into voltage feedback in:

- Linear or rotary actuators

- Robotic joints and end-effectors

- Hydraulic and pneumatic control valves

- Positioning mechanisms in industrial machinery

At Nolelc, servo pots can be customized to match specific application needs, including:

- Resistance angles from 30° to 360°

- Output characteristics (strictly linear or tailored curves)

- Dual or triple output channels for redundancy

- Special housings and shaft interfaces to fit the customer’s mechanical design

This level of customization helps ensure perfect compatibility with the customer’s control logic and mechanical constraints.

7. Summary

A servo potentiometer represents the union of mechanical precision and material science.

- Conductive plastic resistive elements provide smooth, stable, and customizable output.

- Multi-wire wipers and carefully designed brackets ensure reliable, low-noise contact.

- Precision mechanical structures support repeatable positioning and consistent feedback.

With self-developed conductive plastic film technology and multi-wire wiper designs, Nolelc provides high-reliability, long-life servo pots for demanding applications in aerospace, robotics, industrial automation, and beyond.