This article discusses the role of sensors in servo systems. It first outlines the control principles and control architectures of servo systems, then explains the application scenarios of sensors with various accuracy levels in these systems.

1) Dual Classification and Integration of Servo System Control Methods

1.1 Classification by Control Architecture: Open-Loop vs Closed-Loop

Open-loop Control

- There is no feedback mechanism. The controller sends a command without checking the actual result.

-

Typical applications: stepper motor systems (simple pulse control), low-end motion scenarios.

Closed-loop Control

- Features feedback elements (such as potentiometers, encoders, and sensors) to detect actual output and compare it with the set value. The system automatically adjusts based on error to ensure accuracy and reliability.

- Typical applications: servo motor systems, CNC machines, robotics, and other high-precision environments.

1.2 Control Signal Input Methods: Pulse, Analog, Communication

- Pulse: Controls servo motor position or speed by sending a number of pulses and direction signals.

- Analog: Uses continuously varying voltage or current signals to control speed, position, or torque of the motor.

- Communication: Transmits rich information such as position, speed, status, and parameters through digital fieldbus protocols, enabling complex control.

1.3 Practical Application Examples

| Control Structure | Signal Input Type | Typical Application | Feedback Mechanism | Example |

|---|---|---|---|---|

| Open-loop | Pulse | Simple stepper motor positioning | No feedback | Standard stepper driver |

| Closed-loop | Pulse | Closed-loop stepper/servo motor | Encoder/Potentiometer | Servo positioning system |

| Closed-loop | Analog | Industrial automation, speed ctrl | Sensor/Potentiometer | Inverter + encoder |

| Closed-loop | Communication | Smart factory, multi-axis motion | Multiple sensors | EtherCAT bus servo |

| Open-loop (rare) | Analog | Simple speed control, fan control | No feedback | Low-end motor driver |

1.4 Chapter Summary

- Open-loop systems usually use pulse or analog control and are common in low-cost or low-precision scenarios, without feedback.

- Closed-loop systems can accept any input signal—pulse, analog, or communication—but require feedback elements (such as potentiometers, encoders, or sensors) for real-time detection and error correction, achieving high accuracy and reliability.

- Communication is suitable for highly integrated, large-scale systems, making remote control and data exchange easy.

- Modern high-end servo systems commonly adopt closed-loop + communication, while remaining compatible with pulse and analog interfaces to meet various industrial automation needs.

2) Common Servo Feedback Accuracy Terms Explained

2.1 Linearity

- Definition: Linearity refers to the maximum deviation between the actual output and the ideal straight-line output throughout the full scale.

- Example: If a potentiometer specifies linearity as 0.2%FS, its maximum deviation from the ideal output does not exceed 0.2% of the full scale.

2.2 Resolution

- Definition: Resolution is the smallest detectable physical change that the feedback element can sense or respond to—the minimal step.

- Example: If an encoder has a resolution of 0.01°, it can distinguish a minimum angular change of 0.01°.

2.3 Repeatability

- Definition: Repeatability is the maximum difference in output when the same input is measured multiple times, indicating the stability of the component.

- Example: If a sensor has repeatability of 0.05%FS, the maximum difference in output for the same input does not exceed 0.05% of the full scale.

2.4 Hysteresis

- Definition: Hysteresis is the maximum difference in output value when the input signal changes in forward and reverse directions. It mainly appears in sensors with mechanical structures.

- Example: If a potentiometer’s hysteresis is 0.03%FS, the output difference between forward and reverse measurement is at most 0.03% of the full scale.

2.5 The Relationship Between Four Key Parameters and Servo Feedback Accuracy

- Linearity determines the “straightness” of the output, affecting positioning accuracy across the full range.

- Resolution determines how finely a system can distinguish, directly impacting minimum step and fine-tuning ability.

- Repeatability affects system stability and repeat positioning.

- Hysteresis mainly impacts consistency when moving in forward and reverse directions.

In high-precision servo systems, all four parameters are critical. They are usually expressed as a percentage of full scale (%FS) for easy cross-product comparison.

2.6 Comparison Table of Typical Accuracy Parameters in Servo System Sensors

| Parameter | Definition | Typical Unit | Example Description |

|---|---|---|---|

| Linearity | Max deviation from ideal straight line/full scale | %FS | 0.1%FS linearity = max 0.36° error for 360° range |

| Resolution | Min detectable change/full scale | %FS or absolute | 0.01° resolution |

| Repeatability | Max output diff for same input/full scale | %FS | 0.05%FS |

| Hysteresis | Max output diff (fwd/rev) for same input/full scale | %FS | 0.03%FS |

2.7 Linearity VS Resolution

- Linearity reflects the overall “straightness” (max deviation over full range).

- Resolution reflects “how fine the steps are,” i.e., the smallest distinguishable increment.

Sometimes, high resolution does not mean good linearity (possible curve errors).

Servo feedback elements often require both high resolution and high linearity.

2.8 Chapter Summary

-

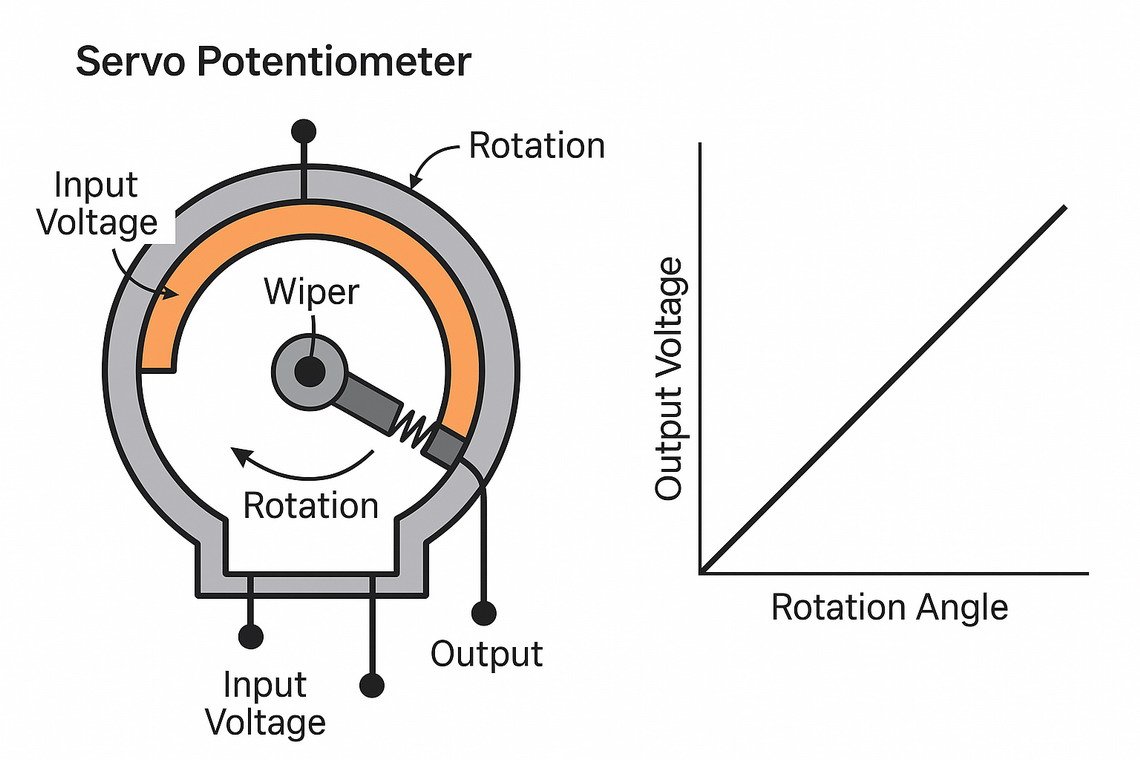

The diagram above shows a basic cross-sectional structure of an angular sensor. The rotating shaft drives the wiper to slide over the arc-shaped resistive element. An input voltage is applied across both ends of the resistive element, while the wiper is connected to the output terminal. As the shaft rotates, the wiper’s position on the resistive element changes, resulting in a linear variation of the output voltage. This achieves a one-to-one correspondence between the rotation angle and the output voltage.

-

In fact, the main purpose of servo technology is to enable the sensor to output a precise, continuously proportional voltage or current signal during rotational or linear motion. Regardless of the specific processes or materials discussed in previous sections, the ultimate goal is that the relationship between the rotation angle (as shown on the right side of the diagram) and the output voltage should ideally be a straight line—or, within the limits of measurement accuracy, as close to linear as possible. This “analog angle–linear voltage” characteristic makes servo sensors particularly well suited for high-precision position detection in servo systems and automatic control applications.

3) Application of Sensors in Servo Systems

3.1 Role of Sensors in Modern Servo Systems

Sensors are not only the core of feedback but also the foundation for high-precision, high-reliability automatic control. Both rotary servo motors and linear motion systems rely on precise sensor feedback.

3.2 Sensors in Rotary Servo Systems

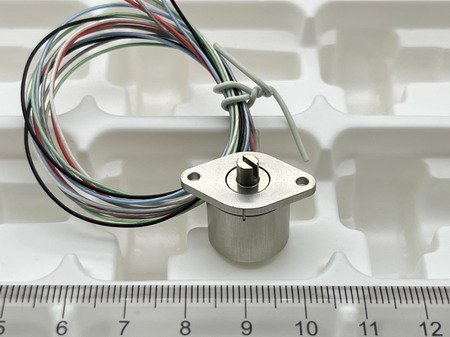

- Rotary servo systems typically use angle potentiometers or encoders as feedback elements.

- Potentiometers are suitable for medium/low speed, cost-sensitive, or adjustment scenarios, achieving 0.1~0.5%FS linearity and up to 0.01° resolution.

- For higher precision and multi-turn measurement, incremental or absolute encoders are used, with resolution up to 0.01° or better—widely applied in robotic joints, CNC machines, and automation equipment.

3.3 Sensors in Linear Motion Servo Systems

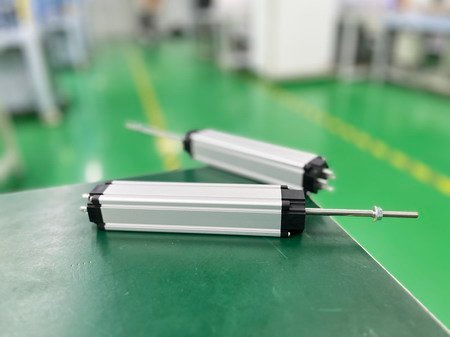

- Linear motion servo systems often use linear potentiometers (electronic rulers), linear encoders, and magnetostrictive displacement sensors.

- These components offer resolution of 0.01mm or better, and maintain high linearity (e.g., ±0.1%FS) across the full range.

- In automated assembly lines, precision measurement, hydraulic cylinder position detection, etc., linear feedback sensors ensure accurate control and repeatable positioning.

4) Industry Segmentation and Typical Product Cases

4.1 Comparison Table of Typical Servo Sensors

| Application | Sensor Type | Typical Brand/Model | Resolution | Linearity | Repeatability | Notes |

|---|---|---|---|---|---|---|

| Industrial Robot | Absolute Encoder | Heidenhain ECN/EQN | 0.01° | ±0.01%FS | 0.005%FS | Multi-turn feedback |

| CNC Machine | Optical Linear Encoder | SICK LMS/Heidenhain | 0.001mm | ±0.01%FS | 0.002%FS | Sub-micron precision |

| Automotive | Rotary Potentiometer | Bourns 6639 | 0.05° | ±0.3%FS | 0.01%FS | Automotive grade |

| Hydraulic Control | Magnetostrictive Sensor | BALLUFF Micropulse | 0.01mm | ±0.05%FS | 0.01%FS | Long-stroke, high accuracy |

| Medical Robot | Miniature Angle Encoder | Novotechnik Vert-X | 0.09° | ±0.1%FS | 0.02%FS | Compact, lightweight |

4.2 Explanation and Example of FS (Full Scale)

In the table above, you may notice that the unit for linearity and repeatability is FS. FS stands for full scale, representing the entire measuring range of the sensor or encoder.

Example: If a linear position sensor has a measuring range of 500 mm:

- Resolution: 0.01 mm

- Linearity: ±0.05%FS (i.e., maximum error is ±0.25 mm; 500 mm × 0.05% = 0.25 mm)

- Alternatively, it can be labeled “Linearity ±0.25 mm”

4.3 Industry Segmentation and Typical Product Cases

Industrial Automation & Robotics

-

Application scenarios: robotic joint angle feedback, automated assembly line positioning, servo actuator position control, etc.

-

Typical products: incremental/absolute encoders (brands like Heidenhain, Renishaw), conductive plastic rotary potentiometers (such as Novotechnik, NOLELC)

-

Key requirements: high resolution (0.01°), multi-turn feedback, strong anti-interference.

CNC Machine Tools & Precision Measurement

-

Application scenarios: linear stage positioning, spindle angle feedback, precision length measurement, etc.

-

Typical products: optical linear encoders (Heidenhain, Fagor, SICK), magnetostrictive displacement sensors (Temposonics, BALLUFF)

-

Key requirements: sub-micron resolution, high linearity (±0.01%FS), very low hysteresis.

Automotive & Rail Transit

-

Application scenarios: electric power steering (EPS), electronic accelerator pedal, brake system position feedback, door control system, etc.

-

Typical products: rotary encoders/potentiometers (Bourns, ALPS), linear position sensors (NOLELC)

-

Key requirements: high reliability, long life, high repeatability.

Aerospace & Defense

-

Application scenarios: flight control servos, radar antenna positioning, missile fin control, etc.

-

Typical products: high-precision absolute encoders (Renishaw, Avago), aerospace-grade conductive plastic potentiometers

-

Key requirements: very high resolution (up to 0.001°), wide temperature range, high vibration resistance.

Medical Equipment

-

Application scenarios: surgical robots, precision infusion pumps, motion control in imaging equipment, etc.

-

Typical products: miniature encoders and potentiometers (Novotechnik, Copal)

-

Key requirements: high accuracy, contamination-free, extremely low hysteresis and drift.

5) Summary

Sensors are the cornerstone of modern servo systems, enabling precise, reliable, and repeatable motion control across a wide range of industries. Choosing the right feedback device—whether potentiometer, encoder, or advanced linear sensor—depends on the application's requirements for resolution, linearity, repeatability, and environmental conditions. As automation and robotics continue to advance, the importance of sensor accuracy and intelligent integration will only grow.