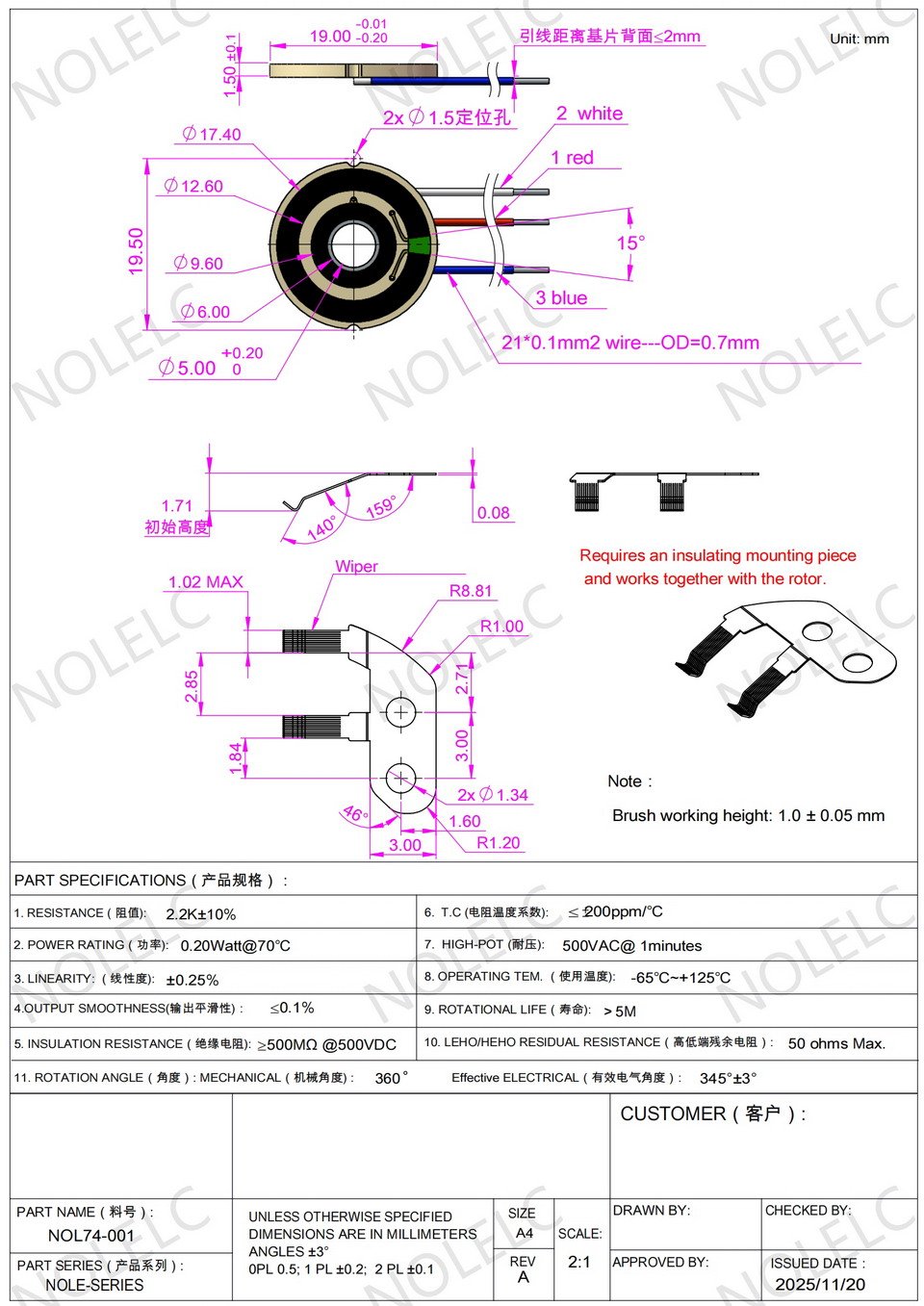

The image shows a CP potentiometer resistive element.

1. Introduction

Conductive-plastic potentiometers have been used in precision control systems for many years.

To keep the discussion clear, this article uses the following short terms:

- Conductive-Plastic Resistance Element → CP Element

- NOL High-Performance Carbon-Film Element → H-carbon-film Element

With improvements in materials and production processes, we offer two practical material paths to replace CP elements. Each path fits different application needs and brings different advantages.

2. Path A — Same-Material Replacement (CP → CP)

This path keeps the same resistive material and the same working principle.

Our CP element can directly replace imported conductive-plastic parts.

2.1 Key Features

- Noise ≈ 100 mV

- Life up to 50 million cycles

- Linearity ±0.25%

- TCR ≈ 200 ppm

- Operating temperature −55°C to +125°C

- Smooth surface and stable running torque

2.2 Suitable When

- The customer already uses CP technology

- Very long lifetime is required

- Mold design cannot change

- A direct “drop-in” replacement is needed

3. Path B — Cross-Material Replacement (CP → H-carbon-film)

This path replaces conductive-plastic with H-carbon-film elements.

For many applications, this path offers similar or even better performance at a lower cost.

4. Why H-carbon-film Elements Can Replace CP Elements

Let’s take a look at a simple specification sheet together.

4.1 Lower Manufacturing Cost

H-carbon-film uses screen printing.

- Screen cost ≈ USD 1000

CP elements require special molds.

- Mold cost ≈ USD 3000

4.2 Lower Noise

- H-carbon-film: ~40 mV

- CP element: ~100 mV

4.3 Larger Effective Electrical Angle

For elements smaller than 32 mm:

- CP element: typically ≤ 350°

- H-carbon-film element: up to 355°

4.4 Practical Lifetime for Real Systems

- H-carbon-film: 5–10 million cycles

Most industrial systems do not reach 10 million cycles in their entire operating life, meaning H-carbon-film is already sufficient for many applications.

5. Core Performance Comparison Table

5.1 Understanding Lifetime Requirements

I have seen a TE specification where the CP element is rated at 100 million cycles, and many customer drawings list 50 million cycles as the requirement. In comparison, H-carbon-film elements offer about 5–10 million cycles. However, when the customer clearly understands their real operating conditions, H-carbon-film often becomes a more cost-effective choice, because most systems never reach such high cycle counts in practice.

5.2 Comparison Table

| Parameter | H-carbon-film Element (NOL) | CP Element (Conductive-Plastic) |

|---|---|---|

| Noise | ~40 mV | ~100 mV |

| Life | 5M–10M cycles | Up to 50M cycles |

| Linearity | ±0.25% | ±0.25% |

| TCR | ~200 ppm | ~200 ppm |

| Effective Electrical Angle | Up to 355° | ≤ 350° (small sizes) |

| Cost | No mold required | Mold required |

| Friction | Lower | Low |

| Environmental Resistance | Oil-resistant, humidity-resistant, washable | Good, but not washable |

| Production Time | Fast | Mold-dependent |

| Typical Applications | Industrial, automation, GJB | Servo-grade, long-life systems |

6. Interpretation

The comparison shows that both materials have their own strengths.

- CP elements: ideal for extremely long lifetime and servo-grade motion systems.

- H-carbon-film elements: deliver lower noise, a larger effective electrical angle, and about 25% lower cost when compared at the same outer diameter.

This is why many industrial clients are moving toward H-carbon-film solutions for cost-effective performance.

7. Summary

Modern H-carbon-film elements provide stable temperature performance, controlled noise, practical lifetime for real industrial systems, and a lower cost structure.

They offer a reliable and economical alternative to CP elements.

Depending on application priorities, both material paths are valid choices.

About NOLELC

Our engineering team helps customers compare the two material paths and choose the best option for their application needs.

With flexible production lines and stable delivery schedules, we support small-batch customization and ensure consistent, reliable performance for global industrial users.