Three representative multi-gang structures: a dual-channel conductive plastic sensor, a multi-gang carbon film potentiometer, and a triple-track conductive element.

In precision control and signal detection systems, multi-gang structures are widely used to achieve multiple resistive paths or signal outputs within limited space.

Depending on the product hierarchy and application scenario, such structures can be categorized into sensor-level, potentiometer-level, and resistive-element-level designs.

While sharing a similar principle, they differ in structure, functionality, and intended purpose.

1. Dual-Channel Conductive Plastic Redundant Sensor

This design represents a sensor-level product, commonly found in aerospace, robotic joints, and industrial servo systems where high reliability is required.

It uses conductive plastic resistive elements and places two independent resistive tracks with separate wipers on a single shaft, forming dual-channel isolated outputs.

Each channel delivers an individual angular or displacement signal, providing both dual output and safety redundancy. When one channel drifts or fails, the other continues to output, allowing real-time comparison or switching to maintain reliability.

Conductive plastic offers low noise, excellent wear resistance, and superior linearity (typically ±0.25%), with lifetimes exceeding several million cycles.

This configuration is often referred to as a Dual-Channel Conductive Plastic Angle Sensor, a mainstream solution for high-reliability position feedback systems.

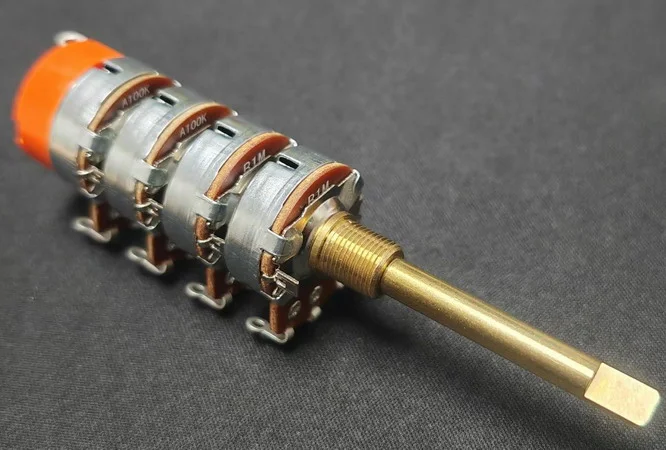

2. Multi-Gang Carbon Film Potentiometer

This is the traditional potentiometer-level design.

Multiple carbon film potentiometer sections are mechanically coupled on a shared shaft, allowing simultaneous adjustment of several signal channels.

Each section has its own resistance value and output terminals, enabling synchronized or independent control of multiple circuits.

Such structures are widely used in audio mixing, power regulation, and instrumentation.

They are simple, cost-effective, and easy to assemble, though their mechanical synchronization accuracy is limited.

Due to moderate wear resistance and linearity, carbon-film multi-gang types are typically used in medium or low-end applications rather than precision systems.

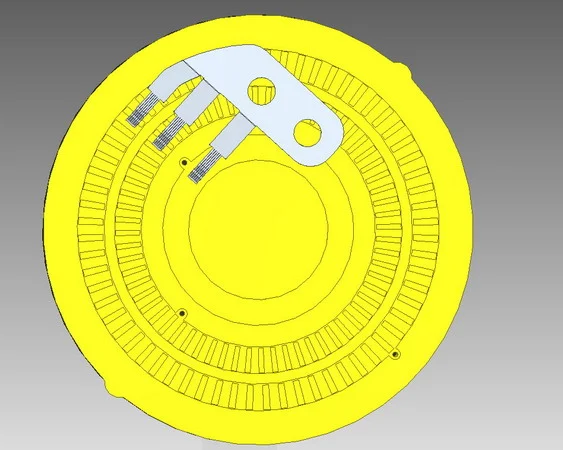

3. Triple-Track Conductive Element Structure

This design belongs to the resistive-element level and is typically used as the core component within precision sensors.

It features three separate conductive tracks formed on the same substrate:

one serves as the common input (excitation or reference), while the other two act as signal output tracks.

Three or more wipers correspond to these tracks, forming a signal structure of one input and two outputs.

This triple-track design enables compact, coaxial signal feedback while maintaining high synchronization.

Because the two output tracks may differ in effective travel or geometric path, parameters such as linearity, resistance gradient, and output range must be redefined and calibrated accordingly.

The result is a compact yet high-precision element capable of dual-signal output under a single excitation reference.

Triple-track elements are particularly suitable for differential detection, limit feedback, dual-signal calibration, or high-end servo control modules.

They represent the extension of multi-gang design principles to the resistive element level, balancing space efficiency with signal consistency.

4. Structural and Application Comparison

| Category | Product Level | Main Structural Form | Output Characteristic | Typical Applications | Key Features |

|---|---|---|---|---|---|

| Dual-Channel Conductive Plastic | Sensor | Dual elements, dual channels | Two fully independent outputs for redundancy | Aerospace, servo systems, robotics | High reliability, long life |

| Multi-Gang Carbon Film | Potentiometer | Multiple units in series | Multi-channel synchronized adjustment | Audio, instrumentation, power control | Simple design, low cost |

| Triple-Track Conductive Element | Resistive Element | Three coaxial tracks | One input, two outputs | Precision feedback, differential detection | Compact size, requires redefined linearity |

Summary

The development of multi-gang structures reflects a transition from multi-control adjustment to redundant feedback design.

Carbon-film potentiometers enabled multi-channel control, triple-track elements achieved dual-signal output in limited space, and conductive plastic sensors brought redundancy and reliability to the highest level.

Together, these designs form a continuous technological chain — from resistive elements → potentiometers → sensors — illustrating the ongoing evolution of resistive displacement detection in space utilization, precision control, and signal safety.