This page helps buyers decide in 2 minutes, and gives engineers the depth to deliver.

1) Quick Selection

Contact allowed?

No → non-contact (Magnetostrictive / LVDT / Optical). Yes → Potentiometric (most economical).

Stroke & life:

Long stroke or >50 M cycles → Magnetostrictive / TLH (rodless track) / LVDT; <5 M & manual control → Potentiometer.

Accuracy target:

≤0.05%FS → Magnetostrictive / LVDT; ≤1%FS → Potentiometer.

Environment & mounting:

Oil/hydraulic → Magnetostrictive; no rod clearance / side-driven guide → TLH; Dust → sealed profile; EMI → 4–20 mA / SSI.

Interface already used:

0–10 V / 4–20 mA / SSI / CAN / Modbus-RTU.

2) Quick Comparison Table

| Type | Best For | Typical Stroke | Accuracy (typ.) | Lifetime | Interfaces | Cost |

|---|---|---|---|---|---|---|

| Magnetostrictive (rod/profile) | Hydraulic cylinders, harsh env., long life | 50–2000 mm | ±0.01–0.05%FS | 100 M+ (non-contact) | 0–10 V / 4–20 mA / SSI / CAN | $$$ |

| LVDT | Precision gauges, aerospace/industrial | 1–300 mm | ±0.25–0.5%FS | 50 M+ | Analog (demod), some digital | $$ |

| Rod-type potentiometric (LWH) | General industrial rod-type, direct absolute measurement | 75–900 mm | ±0.05–0.1%FS (up to ±0.04%FS on longer strokes) | 100 M movements | 0 to voltage supplied (ratiometric) | $$ |

| Rodless profile potentiometric (TLH) | Long guided motion, no rod clearance, side-driven mounts | 100–3000 mm | ±0.05%FS (up to ±0.02%FS) | 100 M+ | 0 to voltage supplied (ratiometric) | $$ |

| Linear potentiometer (manual/motorized) | Faders/HMI, cost-sensitive set-points | 10–300 mm | ±0.5–1.0%FS | 1–5 M cycles | Ratiometric voltage | $ |

Note on LWH and TLH: Both rod-type (LWH) and rodless profile (TLH) belong to the potentiometric family. They still use a resistive track and a moving wiper, but are built as industrial-grade displacement transducers for long strokes and closed-loop feedback. This is why datasheets often call them “transducers,” even though their core principle is potentiometric.

3) Match to NOLELC Families

- Hydraulic cylinders / oil & shock → Magnetostrictive LDT (rod-in-cylinder / profile).

- Injection molding:

• Clamping/tie-bar, short-to-mid strokes (≤900 mm) with rod clearance → Rod-type potentiometric (LWH).

• Long platen travel or side-driven guide (up to 3,000 mm) or no rod space → Rodless profile potentiometric (TLH) (or profile magnetostrictive if non-contact required). - Tight spaces / portable devices → Mini non-contact LDT.

- Human-in-the-loop control → Linear potentiometer (manual or motorized).

4)——— Advanced Explainer ———

4.1 Sensor vs Transducer — Clear Definitions

A transducer converts energy; a sensor is a transducer that detects a stimulus and outputs a usable signal.

In practice, “LDT” ≈ “linear displacement sensor”. We use Sensor as the primary term and include LDT for completeness.

4.2 Core Technologies & How They Work

4.2.1Potentiometric Linear Sensor (Resistive)

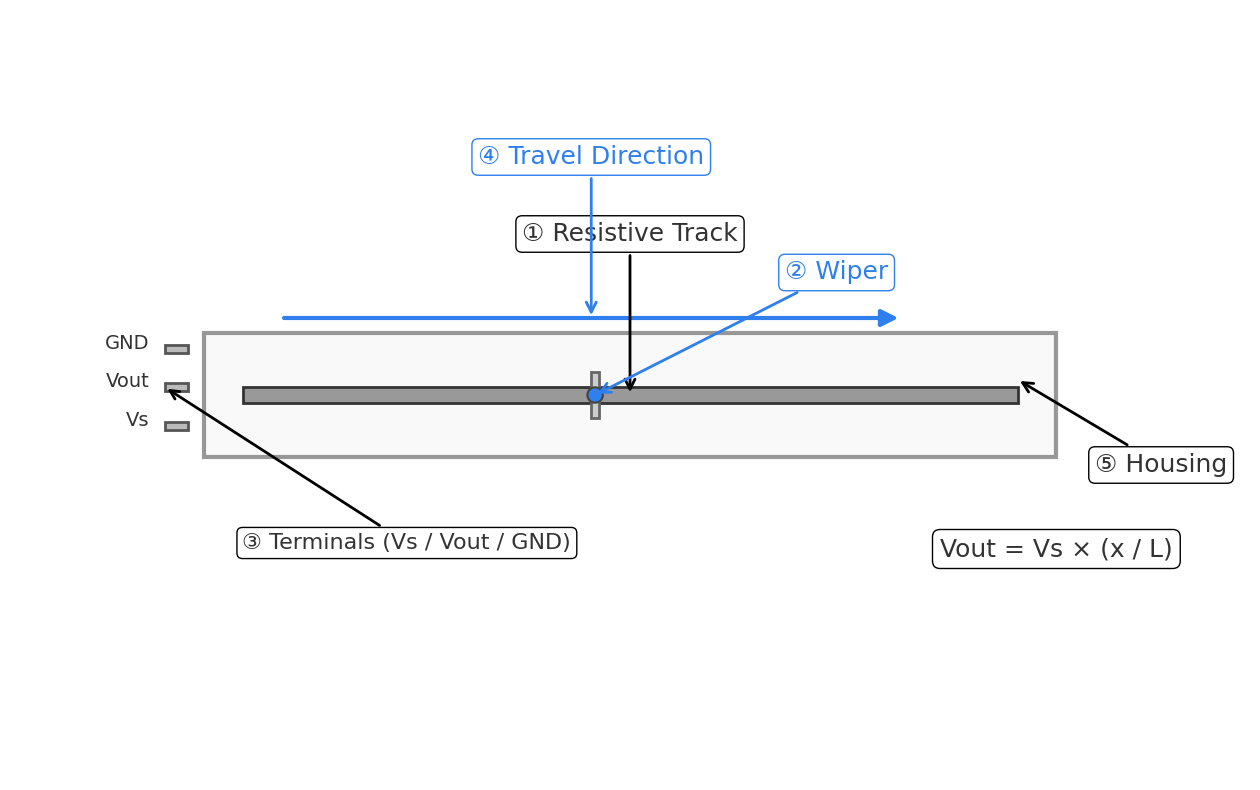

A resistive element and a moving wiper form a divider: Vout = Vs × (x/L) + error. Form factors include rod-type (e.g., LWH) and rodless profile track (e.g., TLH); both are contact-type and output ratiometric voltage.

Pros: simple, low cost, easy ADC read. Cons: wear/contamination, limited life.

4.2.2 LVDT (Linear Variable Differential Transformer)

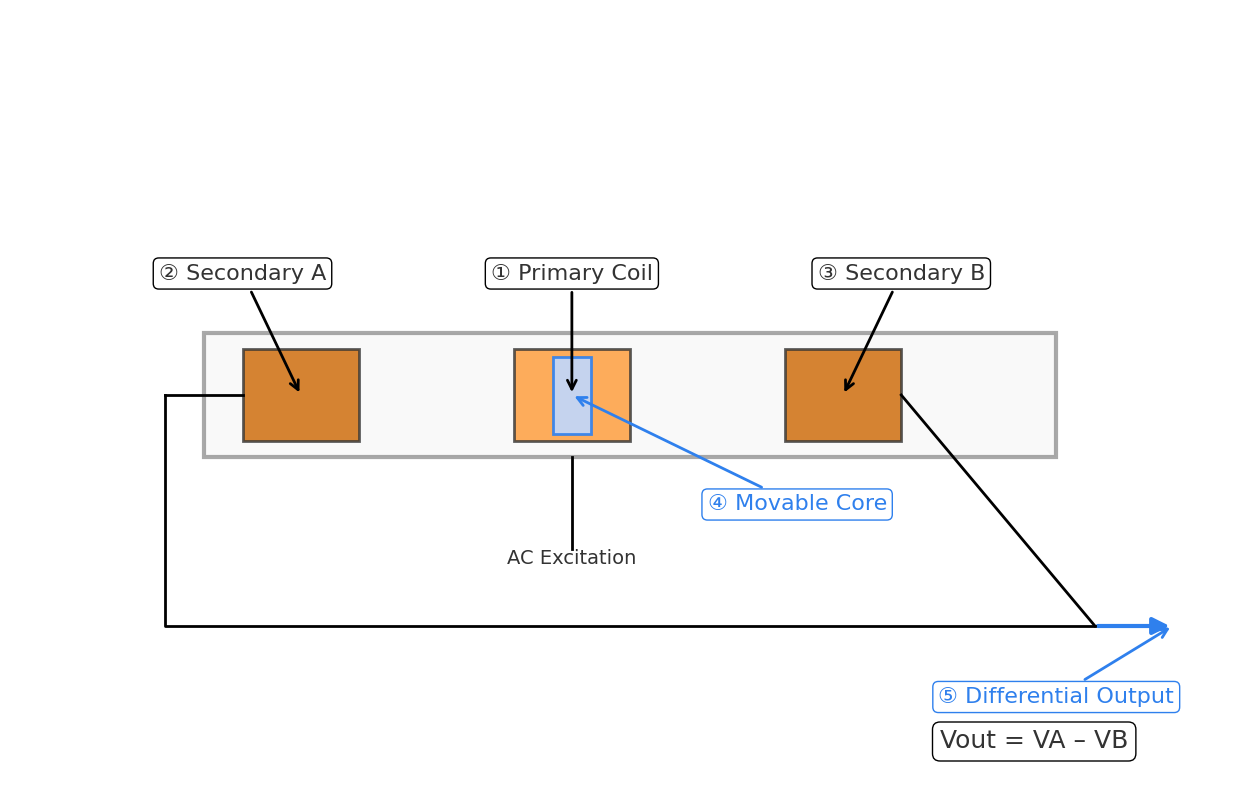

AC-excited primary; two secondaries; movable core shifts coupling; phase-sensitive differential output around null.

Pros: no wear, excellent repeatability, low drift; Cons: needs conditioning electronics.

4.2.3 Magnetostrictive (Rod/Profile)

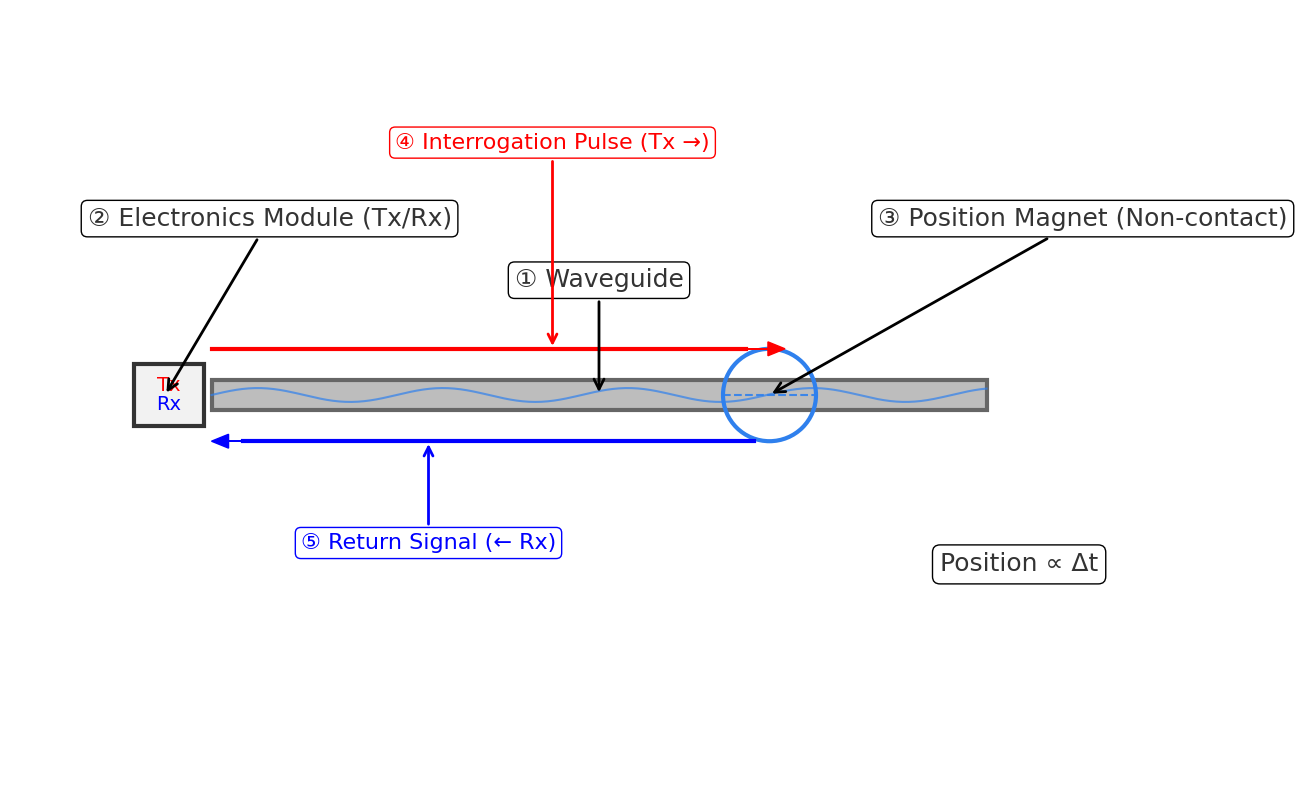

A current pulse interacts with a position magnet along a waveguide; time-of-flight of the torsional wave ∝ distance.

Pros: non-contact, long life, ideal for hydraulic cylinders; Cons: higher cost, EMI-aware routing.

4.3 Key Specs — What They Really Mean (Full)

Accuracy = max absolute error vs. true position.

Linearity = deviation from best-fit straight line.

Resolution = smallest detectable step.

Repeatability = same-point spread.

Hysteresis = forward vs. reverse difference.

Typical ranges by technology (as % of full scale, %FS):

• Potentiometric: ±0.5–±1.0%FS

• LVDT: ±0.25–±0.5%FS

• Magnetostrictive: ±0.01–±0.05%FS

What does %FS mean? “%FS” is the percentage of full scale (FS), where FS is the rated travel of the sensor. “±0.5%FS” means the max error is ±0.5% of the full travel.

Full-Scale Error Examples

| Full Scale (FS) | ±0.5%FS | ±1.0%FS | ±0.25%FS | ±0.05%FS | ±0.01%FS |

|---|---|---|---|---|---|

| 100 mm | ±0.5 mm | ±1.0 mm | ±0.25 mm | ±0.05 mm (50 μm) | ±0.01 mm (10 μm) |

| 500 mm | ±2.5 mm | ±5.0 mm | ±1.25 mm | ±0.25 mm (250 μm) | ±0.05 mm (50 μm) |

Use the row matching your stroke to estimate practical error for each technology tier.

4.4 Selection Decision Tree (Detailed)

Contact → Stroke & Life → Accuracy → Interface → Environment/IP → Mounting space → Cost target.

4.5 Error Budget (Practical)

Worst-case: |Total| ≤ |linearity| + |repeatability| + |temp drift| + |mounting run-out| + |electronics|.

Statistical (preferred): σ_total ≈ sqrt(σ_lin² + σ_rep² + σ_temp² + σ_elec²); add mounting as fixed bias.

4.6 Potentiometer vs Sensor — Use Each Where It Shines

Use linear potentiometer for human-in-the-loop control (mixers, motorized faders, simple set-points) and tight budgets.

Use LDT sensors for automated feedback, long life, harsh environments, or when digital buses (CAN/SSI) are needed.

— End —