Summary

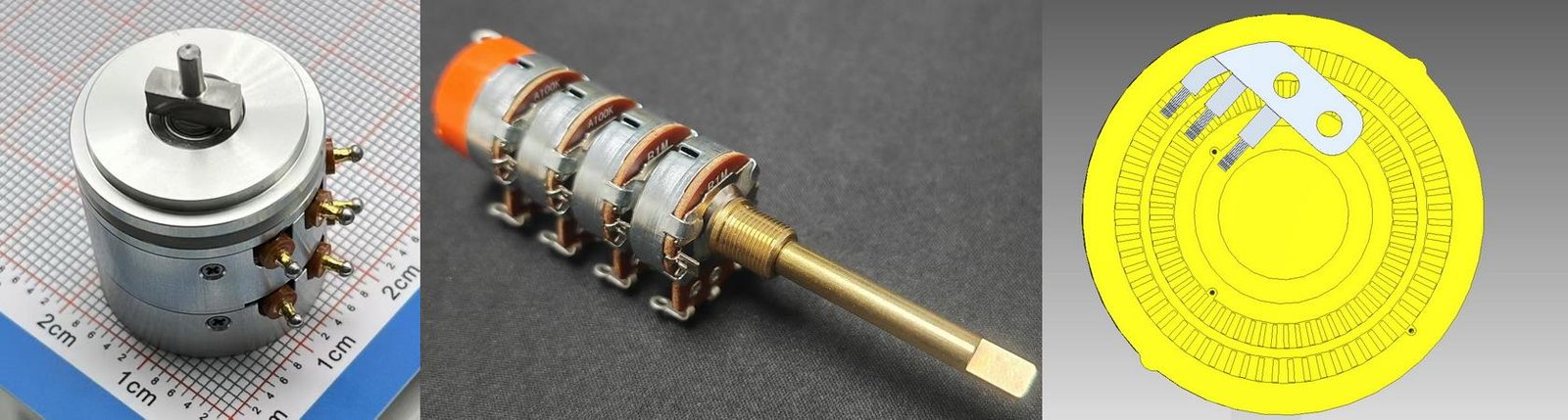

This article explores methods for selecting replacement factories for discontinued potentiometers, analyzing discontinuation reasons, strategies for finding substitutes, and recent affected cases. It guides choosing regions based on production volume and precision needs, using online platforms, exhibitions, and more to ensure product quality and supply chain stability.

1) Why Are Products Discontinued?

1.1 Costs in Europe, America, or Japan/Korea Increase, Leading to No Profit

In recent years, production costs in Europe, America, Japan, and Korea have steadily risen. Rising labor prices, stricter environmental regulations, and increasing energy costs make producing low-margin potentiometers unprofitable. Potentiometers, often used in low-cost electronics, have narrow profit margins, prompting manufacturers to discontinue them for higher-profit products. For example, Bourns may adjust its product lines due to cost pressures (Bourns 3314 Datasheet).

1.2 Mature Industrial Manufacturing Chain System Established in China

China, with low labor costs, supportive government policies, and a large skilled workforce, has built a mature electronics manufacturing chain, becoming a global manufacturing hub. Many companies have shifted production to China to cut costs, leading to the closure of production lines in Europe, America, and Japan/Korea. For instance, Guangdong has become a hub for electronic component manufacturing, reducing potentiometer production elsewhere.

1.32 Other Reasons

Other reasons for discontinuation include:

- Technological Advancements: Digital control technologies are increasingly replacing analog potentiometers, rendering some models obsolete.

- Market Demand Changes: Changes in electronic device designs reduce demand for traditional potentiometers.

- Supply Chain Disruptions: Events like the COVID-19 pandemic, causing raw material shortages or production halts, may force discontinuation (PCBONLINE).

- Regulatory Changes: New environmental or safety standards may make potentiometers non-compliant, leading to discontinuation.

2) Methods to Find Substitute Factories

2.1 Classify Factories Based on Production Volume

When selecting substitute factories, consider production volume. Small factories suit low-volume production, offering high flexibility and low initial costs, ideal for R&D or custom projects. Large factories are better for high-volume production, leveraging economies of scale to meet demand efficiently. For example, Guangdong’s large factories can support high-volume potentiometer production.

2.2 The table highlights the characteristics of key potentiometer production regions:

| Region | Precision | Cost | Production Volume |

|---|---|---|---|

| Fujian | Low | Low | Medium to High |

| Guangdong | High | Medium | High |

| Jiangsu | Medium | Medium | Medium to High |

Different regions in China have unique advantages in electronics manufacturing, and the choice should be based on the precision requirements of the potentiometer:

2.2.1 Fujian: Suitable for Low-Cost Requirements

Fujian is renowned for low production costs, suitable for potentiometers with low precision requirements. However, due to manufacturing process limitations, Fujian factories may not meet high-precision needs, and quality control may be less stringent. When choosing Fujian factories, carefully assess precision and quality standards.

2.2.2 Guangdong: Hub of Electronics Manufacturing

Guangdong is China’s electronics manufacturing core, with numerous factories catering to various production scales and precision needs. Intense competition keeps prices reasonable, but careful supplier vetting is essential for quality. Guangdong factories typically have advanced equipment and strict quality control, meeting high-precision potentiometer production needs.

2.2.3 Jiangsu: Balancing Cost and Precision

Jiangsu balances cost and precision, suitable for medium-precision potentiometer production. Factories offer high-quality products at reasonable prices, ideal for budget-constrained projects needing some precision. Jiangsu’s strong manufacturing base meets general to medium precision requirements.

When inspecting factories, consider time costs, as remote areas or new suppliers may require more time for quality validation. Early communication with factories is recommended to establish clear cooperation processes.

2.3 Other Methods

Other methods to find substitute factories include:

- Online Platforms: Search for electronic component manufacturers on Alibaba or Global Sources.

- Industry Exhibitions: Attend events like the Shenzhen Electronics Show to meet suppliers in person.

- Industry Networks: Seek recommendations from peers or existing suppliers.

- Industry Associations: Contact the China Electronic Components Association for reliable factory lists.

- Google Search: Use keywords like “China potentiometer manufacturers” or “potentiometer factory Fujian”; Google results often include reputable industry websites (Made-in-China).

2.4 Ensuring Manufacturing Quality

When selecting substitute factories, ensuring product quality is critical, especially in low-cost regions like Fujian. Key steps include:

- Quality Control Systems: Ensure factories have rigorous raw material inspection, production monitoring, and product testing processes.

- Partnership: Build long-term partnerships to foster quality improvement and trust.

3) Examples of Recently Discontinued or Price-Increased Potentiometers Due to Tariffs or Factory Issues (2025)

3.1 American Bourns 3314 Series

The Bourns 3314 series is a widely used surface-mount trimmer potentiometer. Although public information does not confirm its discontinuation (DigiKey 3314J-1-103E), industry sources suggest that 2025 tariff increases and factory adjustments may cause supply shortages, price hikes, and extended lead times. Contact suppliers to confirm stock or seek alternative manufacturers in China or elsewhere (Mouser Bourns 3314).

3.2 Japanese HDK VGF39NCHXTB and NVGF6 Series

Japan’s Hokuriku Electric Industry (HDK) VGF39NCHXTB and NVGF6 series are high-precision surface-mount potentiometers used in precision electronics (JLCPCB VG039NCHXTB102). Recently, factory production issues and potential tariff impacts have led to supply constraints and price increases. Although HDK’s website does not confirm discontinuation (HDK Products), proactively seek alternative suppliers in China or elsewhere to stabilize the supply chain.

4) Summary

Potentiometer discontinuation results from rising costs in Europe, America, Japan, and Korea, China’s mature manufacturing chain, technological advancements, market demand shifts, and supply chain disruptions. Select substitute factories based on production volume and precision needs, such as Fujian (low cost, low precision), Guangdong (high precision), or Jiangsu (cost-precision balance). Use online platforms, exhibitions, industry networks, or Google searches to find suppliers, or redesign products to use more accessible components. Quality control and proactive planning are vital for supply chain stability.