1) Introduction:

Something interesting happened recently. I got an email from a flexible OLED manufacturer in Silicon Valley, USA. Honestly, at first, I thought they wanted potentiometer parts, but as we kept talking, the client started describing their flexible OLED production process—and specifically mentioned they were looking for special brush contacts for testing.

I was really surprised—brush contacts for flexible OLED testing? That’s a first for me!

During our follow-up discussions, the client asked a bunch of very technical questions about things like hardness, deformation force, wear resistance, and how not to damage the OLED circuits. Based on their requirements, I recommended a dual-contact brush design that fits their application. The brushes have already been shipped, and now I’m really looking forward to hearing about their results.

Honestly, this experience made me realize just how many new possibilities there are for manufacturing in the tech world. That’s why I decided to write this blog—to share these new ideas and encourage more cross-industry innovation.

2) Reimagining Traditional Applications

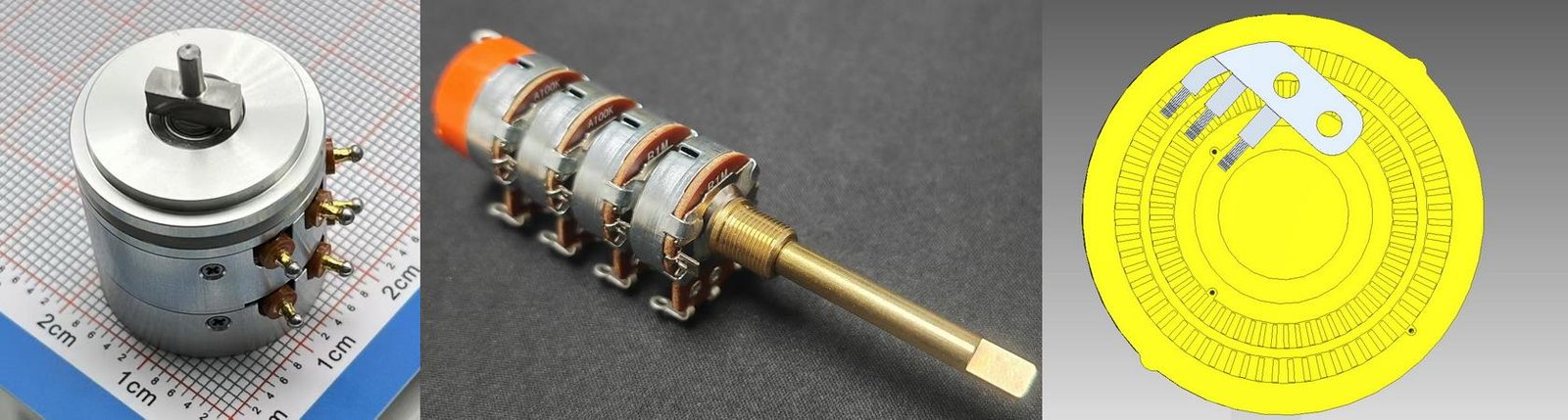

2.1 Precision Sliding Contacts in Potentiometers

Potentiometers are widely used in signal regulation applications, and flexible brush contacts, with their stable multi-point contact characteristics, effectively reduce signal noise and significantly enhance device reliability and lifespan. Customizable alloy brush structures enable potentiometers to deliver stable, accurate signal outputs even under harsh conditions.

2.2 Flexible OLED Panel Testing

Flexible OLED panels require highly sensitive testing methods; traditional rigid contacts risk damaging the screens. Flexible brush contacts, utilizing gentle multi-filament strands, reduce contact pressure and protect panel integrity, significantly enhancing testing accuracy and product yield.

2.3 Membrane Switches and FPC Connections

In membrane switches and flexible circuits (FPC), flexible brush contacts ensure signal integrity through multi-point redundancy, maintaining stable and reliable performance during frequent micro-movements, while minimizing wear and maintenance requirements.

2.4 High-Reliability Connections in Medical Devices

Medical electronic devices demand stringent signal stability and safety. Flexible brush contacts, employing biocompatible noble metals, minimize contact resistance fluctuations, ensuring precise and stable long-term signal transmission.

3) Expanding Innovation into Emerging Fields

3.1 Wearable Electronic Devices

Flexible brush contacts, characterized by their exceptional flexibility, adapt perfectly to frequent movements and bends in smartwatches and health monitoring devices, offering stable and comfortable electrical connections.

3.2 Automotive Electronics Applications

Position and angle sensors in automotive electronics demand vibration-resistant and shock-proof connections. Flexible brush contacts, with their redundant multi-point contact design, ensure reliable and stable sensor outputs even under severe environmental changes.

3.3 Industrial Sensor Applications

Industrial automation environments pose challenges due to high vibration and impact on connection stability. Flexible brush contacts offer stable and durable multi-point interfaces, effectively extending sensor lifespan and operational stability.

4) Terminology Clarification

The term \"Flexible Brush Contacts\" generally refers to a contact system composed of precision-stamped elastic metal bases combined with multiple fine filaments. Often also called \"Sliding Contacts\" or \"Multi-Fiber Contacts,\" these terms slightly differ but all fundamentally describe elastic multi-point electrical connection components.

5) Customization Features & Conclusion

The successful implementation of flexible brush contacts is closely tied to their high customization capability. By customizing brush filament structures, material selections, and electrical properties, these contacts precisely meet the specific demands of various fields. For instance, engineers can adjust filament counts and arrangements to optimize contact pressure and signal stability, select different alloys and coatings to enhance wear resistance and oxidation protection, and finely tune contact resistance, rated currents, and noise immunity to meet specific electrical requirements. Customers can flexibly tailor these contacts according to their needs, enabling exceptional performance and reliability across traditional and emerging application areas.

As a professional manufacturer of flexible brush contacts, NOLELC is able to tailor brush products of various specifications, materials, and structures to your requirements. Whether for mass production or small-scale development, we provide efficient, flexible, and competitive customized solutions. If you are seeking a reliable partner for flexible brush contacts, feel free to contact NOLELC — we are ready to support your product upgrades with professionalism and integrity.