Summary

Discover the unique advantages of NOLELC’s custom potentiometer brushes featuring precision-crafted precious metal alloy contacts and robust CuBe2 spring bases. Engineered for longevity, high-frequency applications, and customized OEM integration, our brushes deliver consistent performance in automotive, industrial, and flexible electronic sensors.

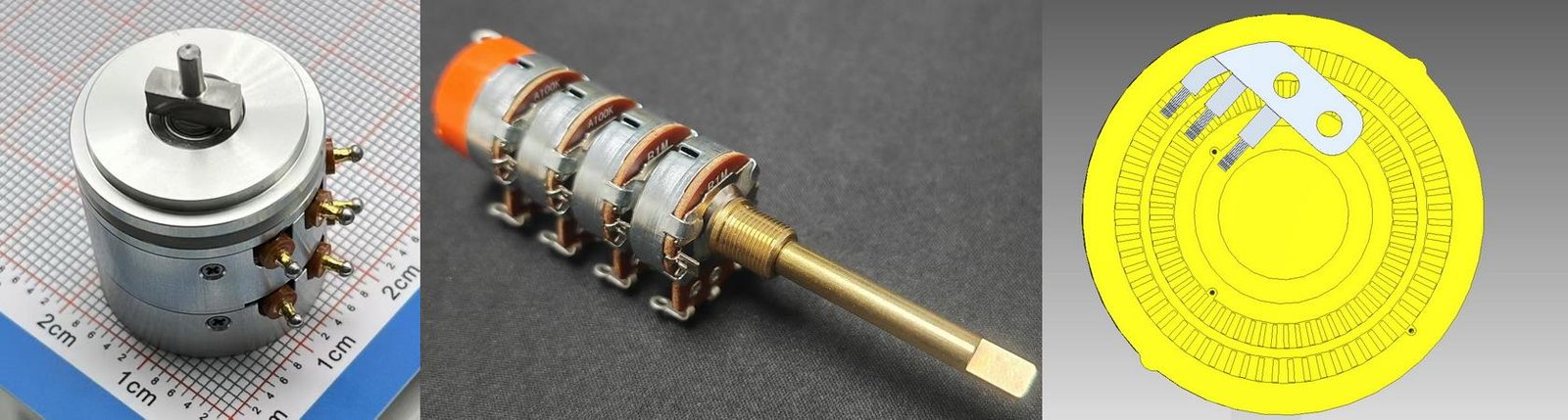

1) Precision and Durability: NOLELC’s Custom Potentiometer Brushes

Modern sensor technology demands exceptional reliability and precise electrical signals. Among key components determining sensor quality, the potentiometer contact brush plays a crucial role. This article introduces NOLELC’s premium custom potentiometer brush, highlighting its extraordinary longevity, advanced alloy wire contacts, precision CuBe2 base, and proven success across demanding industrial applications.

2) Engineered for Exceptional Longevity: Over 3 Million Cycles

Our custom potentiometer brush achieves over 3 million mechanical cycles—far exceeding standard brushes, typically rated around one million cycles. Such durability translates directly to reduced sensor downtime, enhanced reliability, and significant maintenance cost savings for industries relying on accurate and consistent performance.

This remarkable longevity results from carefully selected materials combined with precision engineering. The brush incorporates a resilient precious metal alloy wire contact and a hardened CuBe2 alloy base, both designed specifically to withstand continuous friction without significant degradation or signal instability.

3) Advanced Precious Metal Alloy Contact Wire: Stable Signals, Minimal Wear

Central to NOLELC’s brush design is our proprietary precious metal alloy contact wire—a sophisticated blend containing gold, silver, platinum, palladium, copper, and zinc. This carefully balanced multi-metal alloy provides numerous performance benefits:

- Superior Conductivity: Gold and silver content ensure consistently low resistance and stable electrical output.

- Enhanced Corrosion Resistance: Platinum and palladium enhance resistance to oxidation, maintaining signal integrity even under harsh automotive or industrial environments.

- High Mechanical Durability: With controlled hardness (HV 240–330), the alloy wire maintains its structural integrity, resisting flattening and deformation even after extensive mechanical cycling.

Our precious metal alloy wire delivers significantly superior performance compared to conventional single-metal contacts, guaranteeing stable, accurate sensor readings throughout the component’s lifespan.

4) Robust CuBe2 Base: Precision Engineered Stability

Supporting our precious metal alloy wire contact is a meticulously crafted CuBe2 (Copper-Beryllium) alloy base. At just 0.12 mm thickness, the CuBe2 base offers exceptional properties essential to reliable brush performance:

- Consistent Spring Force: Ensures uniform pressure against sensor tracks, preventing intermittent signals or excessive wear.

- Dimensional Precision: Manufactured to tight tolerances (±0.1–0.2 mm), facilitating smooth, jitter-free operation and precise sensor integration.

- Outstanding Fatigue Resistance: Retains mechanical strength and elasticity through millions of operational cycles, effectively withstanding repeated flexing under high-frequency conditions and wide temperature ranges (-40°C to +125°C, up to +250°C in special cases).

The combination of our precious metal alloy wire and CuBe2 base guarantees optimal electrical conductivity, robust mechanical stability, and long-lasting reliability.

5) Structural Overview of NOLELC’s Potentiometer Brush

The simplified structure below demonstrates key components clearly:

[ Precious Metal Alloy Wire Contact ]

↑

| (Securely attached to base)

|

┌────────────┴───────────────┐

│ CuBe2 Spring Base │

│ ● │ ← Mounting Hole

└────────────────────────────┘Fig: Structural overview—The precious metal alloy contact wire provides reliable electrical connection, while the CuBe2 spring base ensures consistent mechanical pressure and secure attachment.

6) Proven in High-Frequency and Precision Applications

Our potentiometer brush excels in applications requiring precise positional feedback under rigorous conditions:

-

Automotive Thick-Film Circuit Sensors: Ideal for throttle position sensors, steering sensors, and other automotive sensor modules, delivering stable and noise-free signals despite continuous vibration and frequent positional changes.

-

High-Precision Potentiometers (e.g., 6915 Series): Meets and exceeds demanding linearity, low noise, and consistent performance standards in premium rotary potentiometers used in aerospace, military, and high-end industrial controls, ensuring stable, reliable measurements over extensive operational life.

NOLELC’s brush handles both rapid mechanical cycling and high-frequency signals effortlessly, maintaining clear, stable readings essential for advanced sensor systems.

7) Tailored OEM Solutions and Rapid Customization

Recognizing diverse industry requirements, NOLELC provides extensive OEM customization and rapid prototyping services:

- Drawing and Sample-Based Manufacturing: Precisely match your unique specifications, whether provided by technical drawings or existing samples.

- Rapid Prototyping & Tooling: Quick turnaround for prototype samples and tooling development enables rapid product validation and swift transition into mass production.

- Fully Customizable Parameters: Adjustments in alloy compositions, spring tension, dimensions, and contact configurations tailored specifically to your application needs and environmental conditions.

Our collaborative approach ensures perfect integration of our potentiometer brush into your sensor systems, delivering customized solutions that precisely meet your performance criteria.

Conclusion: Elevate Sensor Performance with NOLELC’s Potentiometer Brush Solutions

In conclusion, NOLELC’s custom potentiometer brush, featuring precision precious metal alloy wire contacts and robust CuBe2 bases, sets new industry standards for reliability, durability, and customization in sensor components. Proven across automotive sensors, flexible displays, and precision industrial potentiometer applications, our brushes consistently deliver superior electrical performance, prolonged lifespan, and outstanding mechanical stability.

Interested in enhancing your sensor’s performance and reliability? Contact NOLELC today for a tailored quotation, customized samples, or to discuss your specific OEM needs. Let’s work together to engineer exceptional sensor solutions.