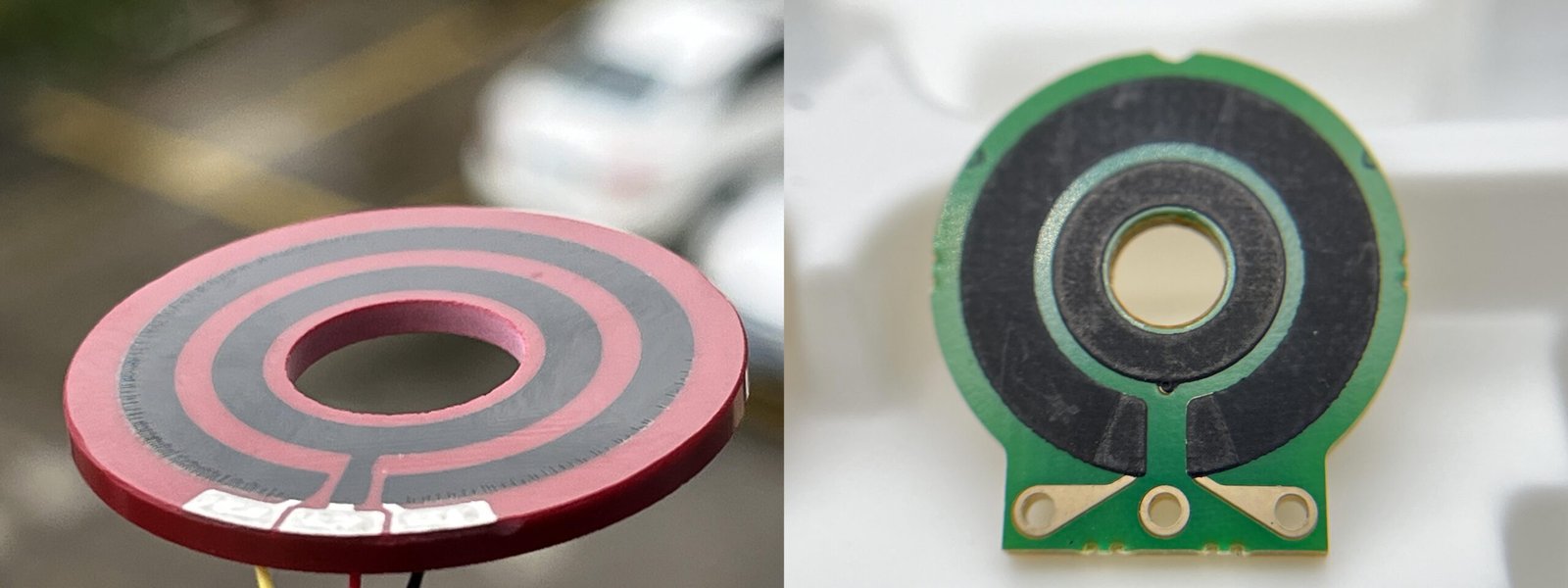

Comparison between conductive plastic and carbon film resistive elements. Both designs follow a circular motion track for the wiper, but the conductive plastic element is thinner and smoother, while the carbon film element shows a visibly thicker printed layer.

Conductive plastic delivers smooth feel, tight linearity, and long life—built for servo-grade control.

Unlike carbon film, the pressed conductive-plastic track offers near-continuous resolution, low noise, and stable performance over temperature and time.

1) What Is a Conductive Plastic Potentiometer?

A CP potentiometer uses a polymer composite resistive track; a wiper moves along it to form a precision divider for position or gain control.

Its hallmark is a pressed, ultra-smooth track that yields low contact resistance variation (CRV) and excellent linearity.

2) Potentiometer vs Servo-Grade Sensor — Plain Language

Potentiometer — adjusts things.

You rotate (round) or slide (linear) it, and the voltage division changes; the device downstream gets more or less voltage/current, so you hear louder/softer volume or see faster/slower speed.

Sensor — measures position and reports it.

As the position moves, it outputs an accurate voltage or current that represents that position to the controller or readout. The controller uses this feedback to close the loop and hold the target precisely.

Why a “servo-grade” sensor matters.

The better the linearity, resolution, and temperature stability, the more precise the feedback and the steadier the control.

Quick contrast

| Item | Potentiometer | Servo-grade Sensor |

|---|---|---|

| What it does | You adjust it to change behavior | It measures & reports position |

| Output | Variable divider → downstream V/I up or down | Position-linked V/I for controller |

| Closed loop? | No (component only) | Yes (enabler) via controller |

| Use cases | Volume, speed trims, one-shot setup | Servo axes, angle/position feedback |

3) Origin & Evolution

Conductive plastic (CP) emerged to solve two pain points: noise/wear of carbon film and ripple/limited resolution of wirewound.

3.1 Timeline

| Period | Milestones | Why it mattered |

|---|---|---|

| 1950s–1960s | Precision trimmers & panel pots mature; polymer/binder research starts | Path to smoother-than-wirewound & more-stable-than entry carbon film |

| Late-1960s–1970s | Birth of CP tracks; early CP rotaries/sliders in precision control & premium audio | Lower contact noise & micro-bumps; smoother feel vs carbon film |

| 1980s | Process discipline; precious-metal multi-wire wipers; sealed housings | Lower CRV & longer life; industrial duty ready |

| 1990s | Servo-grade refinement: ±0.25%–±0.5% typical linearity; wear-resistant fillers; dual/tri tracks | Loop-ready accuracy & safety diagnostics |

| 2000s | IP54–IP65 sealing; >5M cycles common; thin-profile rotaries & long-stroke sliders | Wider environments & easier integration |

| 2010s–Today | Co-exists with non-contact (Hall/inductive); CP remains the contacting choice when feel/linearity/TCO dominate | Designers pick by price–performance tier & lifecycle goals |

3.2 What Improved Inside CP — Key Factors

| Domain | What improved | Effect on performance |

|---|---|---|

| Materials | Tighter filler PSD; stable binders; tailored internal lubricants | Lower wear & CRV; better batch consistency |

| Surface | Pressed-film uniformity + finishing | Fewer micro-asperities & micro-arcing; lower noise |

| Contacts | Precious-metal multi-wire wipers | CRV greatly reduced; life extended |

| Mechanics | Controlled shaft torque; better bearings/bushings; rigid housings | Track–wiper geometry stable under load/vibe |

| Architecture | Dual/tri tracks; custom tapers; diagnostics | Safety redundancy & easier calibration strategies |

| Environment | IP sealing; venting/moisture control; corrosion-tolerant metals | Reliable in harsh duty; stable long-term drift |

4) Appearance Differences vs Carbon Film

Track flatness: CP tracks look almost perfectly smooth; carbon film shows granularity and micro-bumps under magnification.

Color/texture: CP appears deep black/grey and fine; carbon film tends to lighter grey/brownish with visible texture.

Build cues: CP parts often feature robust housings, refined terminals, and IP sealing; carbon film skews lighter and more consumer-grade.

5) Performance (Typical Ranges)

Values are indicative; verify against the target datasheet.

| Metric | Conductive Plastic | Carbon Film |

|---|---|---|

| Linearity | ±0.25%–±0.5% (typ.) | ±2%–±5% (typ.) |

| Resolution | Near-continuous; wiper-limited | Coarser; grain-affected |

| Noise / CRV | Very low (esp. multi-wire) | Higher |

| Life (cycles) | ≥5,000,000 common | ~100k–500k common |

| TCR | ~±100–±300 ppm/°C | ~±600–±1500 ppm/°C |

| Temp drift | Low | Higher |

| Sealing | IP options common | Less common |

Takeaway: Choose CP when servo-grade linearity, stability, and life outweigh BOM cost.

Note — Linearity vs stroke (why longer can be tighter)

Rule of thumb: for linear potentiometric sensors with conductive-plastic tracks, independent linearity (% of full stroke) often improves as the stroke gets longer.

Why

1) The same absolute deviation occupies a smaller % of a larger full scale.

2) Longer tracks average more micro-variations in the resistive path and benefit from more uniform process control.

Industry examples (indicative, not brand-specific)

- LWH-type linear transducers (≈75–900 mm stroke): around ±0.10% @ 75–100 mm improving to ±0.04% @ 750–900 mm.

- TLH-type rodless linear transducers (≈100–3000 mm stroke): around ±0.10% @ 100 mm improving to ±0.02% @ 2000–3000 mm.

Datasheet note: These figures usually assume use as a voltage divider with near-zero wiper load (≤ ~1 µA); heavier loading can degrade linearity.

Mini table (illustrative)

| Series | Stroke | Independent linearity |

|---|---|---|

| LWH-type | 75–100 mm | ≈ ±0.10% |

| LWH-type | 750–900 mm | ≈ ±0.04% |

| TLH-type | 100 mm | ≈ ±0.10% |

| TLH-type | 2000–3000 mm | ≈ ±0.02% |

If you need long-stroke, low-%FS linearity solutions, feel free to leave a note so we can discuss real-world conditions and production cost.

6) Do you really need servo-grade sensors? (Conductive plastic vs carbon film)

This quick checklist helps you decide when to choose a conductive-plastic-potentiometer–based servo-grade position sensor instead of a carbon-film potentiometer.

Meet ≥2–3 items below → prefer CP servo-grade; otherwise carbon film is usually fine.

- High accuracy/repeatability: allowable error ≲ ±0.1–0.5%FS or tasks like PCB dispensing/pick-place at ±0.1 mm.

- Linearity/resolution sensitive: avoid micro-hunting and re-tuning; want set-and-stay stable.

- Heavy duty life: frequent reversals; expect ≥1–5 million cycles; downtime is expensive.

- Harsh environment: need lower TCR and IP sealing (outdoor, vibration, dust/oil mist).

- HMI feel matters: knobs/joysticks require smooth, low-noise action (medical, pro-audio, premium consoles).

Typical picks

- Closed-loop & stability critical (robot joints, valve positioners, gimbals, motorsport/industrial actuators) → CP servo-grade.

- One-time set or low-demand trims (basic volume/brightness, light duty speed) → carbon film.

7) Applications (CP-centric)

Servo controls & robotics: machine-tool handwheels, robot joints, industrial joysticks, valve positioners, camera/UAV gimbals.

Automotive & vehicles (select niches): in motorsport and certain industrial vehicles, CP potentiometric sensors are used for throttle/actuator feedback where smooth feel and linearity are prioritized.

Medical & audio: human-machine interfaces needing smooth torque and low noise; premium audio volume controls.

Note: mainstream APS/TPS often use thick-film carbon hybrids; CP appears where performance outweighs cost.

8) Why CP Costs More — and Why It’s Worth It

Measured performance → less tuning. Tight linearity/low CRV cut loop-tuning and calibration effort.

Long life → fewer replacements. Multi-million cycles reduce downtime and service.

Stable over temperature → less drift management. Lower TCR keeps accuracy longer.

Sealing & robustness → broader environments. IP housings and robust tracks suit harsh settings.

TCO often drops despite higher unit price.

| Cost Dimension | CP | Carbon Film |

|---|---|---|

| Unit price | Higher | Lower |

| Calibration & tuning | Lower | Higher |

| Service & replacements | Lower | Higher |

| Uptime & yield | Higher | Lower |

| TCO (overall) | Often lower | Often higher |

9) FAQ (CP-centric)

Q: Is CP overkill for low-end consumer knobs?

Often yes—carbon film is acceptable for non-critical, low-duty adjustments.

Q: Can CP replace wirewound in precision controls?

For many tasks, yes; CP avoids wirewound ripple and feels smoother, though ultra-high power still favors wirewound.

Appendix: Why Compare Conductive Plastic with Carbon Film?

They’re the two most common contacting technologies in the same form factors—buyers usually choose between them.

Same operating principle: both use a wiper sliding on a resistive film, so wiring and signal behavior are comparable.

Similar drop-in packages: rotary/slider footprints and shafts often match, enabling true replacements.

Clear price–performance step: carbon film is cheaper; CP costs more but brings tighter linearity, lower CRV, and longer life.

Why not wirewound or non-contact first? Wirewound targets high-power niches with tactile ripple; non-contact is a different class (EMC/magnetics/diagnostics).

One-liner: CP vs carbon film are the most interchangeable contacting options for the same footprints.