The photo compares two types of high-temperature silver-plated wires specified in different military standards.

On the left is the Chinese GJB-series wire, consisting of 19 strands of 0.08 mm silver-plated copper conductors. Each strand is relatively thick, designed for mechanical strength and current-carrying capacity, resulting in strong tensile resistance but limited flexibility.

On the right is the U.S. MIL-DTL-16878/6 standard wire, composed of 65 strands of 0.025 mm silver-plated copper. Each filament is extremely fine, providing smooth conductivity and outstanding flexibility. The ultra-fine multi-strand construction minimizes skin effect and high-frequency loss.

Both wires are insulated with Teflon (PTFE) jackets, known for excellent high-temperature resistance, dielectric strength, and chemical stability.

This comparison clearly highlights the design philosophy of the two standards: the Chinese GJB wire emphasizes structural robustness, while the U.S. MIL wire focuses on flexibility and electrical precision.

This article compares MIL-DTL-16878 and GJB 773B-2015, focusing on fluoropolymer-insulated wires and cables (PTFE, FEP, ETFE).

The goal is to help engineers and sourcing managers understand how to map one system to the other in real engineering projects.

1. Why Compare These Two Standards?

In global defense and aerospace projects, engineers often face a simple but costly problem:

The same type of high-temperature wire carries completely different part numbers in US and Chinese standards.

On Western drawings you often find notations such as:

- MIL-DTL-16878/4 (Type E) — Medium-wall PTFE insulation, 600 V rating

- MIL-DTL-16878/5 (Type EE) — Heavy-wall PTFE insulation, 1000 V rating

- MIL-DTL-16878/6 (Type ET) — Thin-wall PTFE insulation, 250 V rating – commonly used for internal wiring

These codes may look cryptic, yet together they define almost all Teflon high-temperature hook-up wires used throughout US military equipment.

In the Chinese military and aerospace system, the same functions appear under very different designations:

- GJB 773B FF4 series — Thin-wall PTFE or FEP insulation, 250 V class

- GJB 773B FF40 series — Medium-wall PTFE insulation, 600 V class

- GJB 773B FF46 series — Cross-linked ETFE (XETFE) insulation, up to 260 °C

From a materials and structure perspective, the two systems align closely:

| Equivalent Relation | Insulation System | Typical Max Temp | Voltage Rating |

|---|---|---|---|

| Type ET ↔ FF4 | PTFE thin-wall / FEP | 200 °C / 260 °C (nickel conductor) | 250 V |

| Type E ↔ FF40 | PTFE medium-wall | 200 °C / 260 °C | 600 V |

| Type EE ↔ FF46 | XETFE cross-linked | 200 °C / 260 °C | 1000 V |

Understanding these equivalences brings three direct benefits:

- You can read and interpret foreign drawings without repeated clarification.

- You can propose equivalent or alternative constructions using your own supply chain.

- You can clearly document risk and justification when substituting GJB wires for MIL wires in aerospace programs.

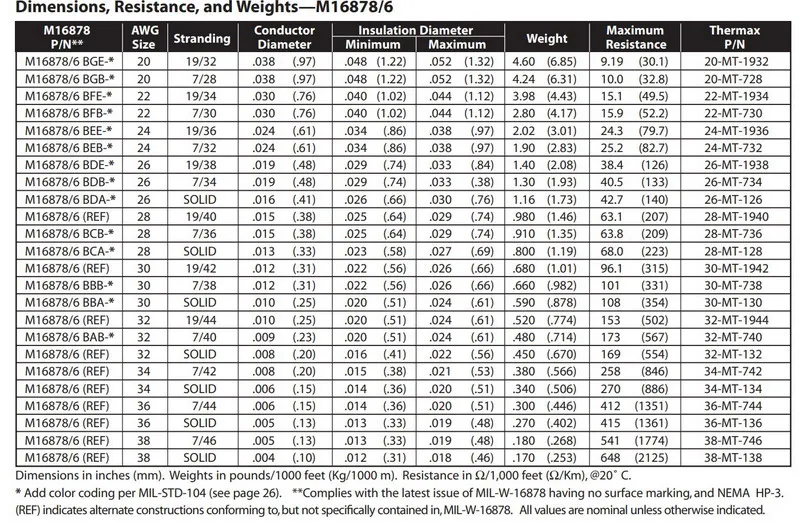

2. What Is MIL-DTL-16878?

MIL-DTL-16878 is a long-standing US military specification for high-temperature internal hook-up wiring, covering PVC, XLPO, and PTFE insulation systems.

The PTFE families most relevant to high-temperature service are:

- Type ET (M16878/6) – Thin-wall PTFE, 250 V

- Type E (M16878/4) – Medium-wall PTFE, 600 V

- Type EE (M16878/5) – Heavy-wall PTFE, 1000 V

Typical temperature classes:

- –55 to +200 °C for silver-plated copper

- –55 to +260 °C for nickel-plated copper

3. What Is GJB 773B-2015?

GJB 773B-2015, General Specification of Fluoropolymer Insulated Wires and Cables for Aerospacecraft, is the Chinese military’s unified standard for fluoropolymer-insulated wires and cables, superseding GJB 773A-2000.

It covers:

- Conductors: tinned, silver-plated, and nickel-plated copper

- Insulations: PTFE, FEP, ETFE, cross-linked ETFE (XETFE), and PVDF

- Applications: both single-core wires and multi-core cables

4. Temperature-Class Comparison

| Item | MIL-DTL-16878 (PTFE types) | GJB 773B-2015 (fluoropolymer types) |

|---|---|---|

| Typical Low Temp | –55 °C/–65 °C | –65 °C |

| 150 °C class | Rare (ETFE types elsewhere) | ETFE insulation / tinned copper |

| 200 °C class | PTFE + silver-plated copper | PTFE / FEP / XETFE + silver-plated copper |

| 260 °C class | PTFE + nickel-plated copper | PTFE + nickel-plated copper |

Both standards overlap almost perfectly; GJB simply extends the low-temperature limit to –65 °C.

5. Conductors and Insulation Systems

| Aspect | MIL-DTL-16878 | GJB 773B-2015 |

|---|---|---|

| Conductor Plating | Silver / Nickel-plated Cu | Tinned / Silver / Nickel-plated Cu |

| Insulation Materials | PTFE only | PTFE / FEP / XETFE / PVDF |

| Application Focus | Ships, aircraft, electronics | Aerospace, vacuum environments |

| Extra Tests | Electrical and mechanical only | Adds vacuum outgassing, toxicity, odor tests |

In short:

MIL-DTL-16878 acts as a broad industrial and defense family, while

GJB 773B-2015 is a refined aerospace subset with additional environmental criteria.

6. Why Almost All High-Temperature Military Wires Use Teflon (PTFE)

Among all insulation materials, Polytetrafluoroethylene (PTFE, Teflon) stands at the top for thermal endurance and chemical inertness.

Both standards place it at their highest temperature tier.

| Standard | Type / Series | Conductor Type | Temp Range | Voltage | Material Characteristics |

|---|---|---|---|---|---|

| MIL-DTL-16878 | Type ET / E / EE | Silver- or Nickel-plated Cu | –55 / –65 to +200 / +260 °C | 250 / 600 / 1000 V | PTFE (Teflon) thin / medium / thick wall construction |

| GJB 773B-2015 | FF4 / FF40 / FF46 | Tinned / Silver- / Nickel-plated Cu | –65 to +200 / +260 °C | 250 / 600 / 1000 V | Fluoropolymer insulation (PTFE / FEP / XETFE) |

6.1 Advantages

- High temperature resistance (200 °C continuous, 260 °C with nickel)

- Excellent chemical inertness against fuels and fluids

- Outstanding dielectric performance (ε ≈ 2.1)

- Extremely low aging rate and long service life

6.2 Disadvantages

- High material and processing cost

- Low flexibility and slippery surface

- Requires controlled stripping and soldering temperatures

6.3 Summary Comparison

| Feature | MIL-DTL-16878 | GJB 773B-2015 | Remarks |

|---|---|---|---|

| Primary Material | PTFE only | PTFE / FEP / XETFE | GJB covers more fluoropolymers |

| Conductor Options | Silver / Nickel | Tinned / Silver / Nickel | GJB adds mid-temperature choice |

| Temp Range | –55 to +200 / +260 °C | –65 to +200 / +260 °C | GJB slightly broader low end |

| Environmental Tests | Standard conditions | Vacuum, outgassing, toxicity | Aerospace-specific tests |

Essentially, at the PTFE tier the two are “cousin standards”—technically parallel though born from different systems.

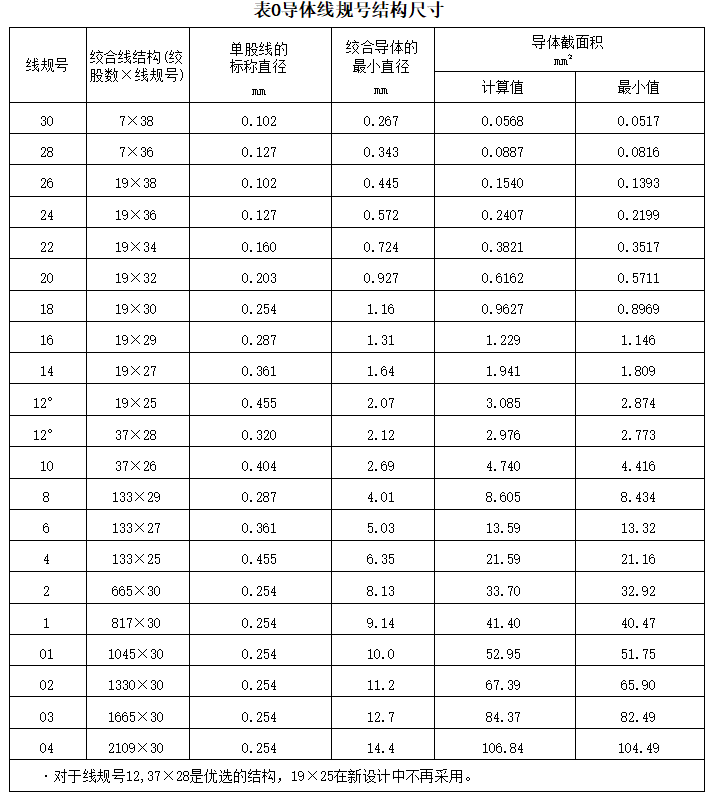

7. Dimensional Definitions: The U.S. Measures Outside, China Measures Inside

A common confusion arises when comparing tables:

“Why doesn’t 22 AWG from MIL and GJB have the same diameter?”

Because each standard defines a different measurement baseline.

7.1 MIL-DTL-16878 — Finished Wire Diameter

- Insulation Diameter Min/Max = overall wire diameter including insulation.

- It controls fit into terminals and connectors.

7.2 GJB 773B-2015 — Bare Conductor Diameter

- Comprehensive Conductor Minimum Diameter = finished stranded conductor diameter before insulation.

- Insulation thickness and finished OD are defined elsewhere.

| Perspective | MIL-DTL-16878 | GJB 773B-2015 |

|---|---|---|

| Measurement Object | Finished wire (incl. insulation) | Conductor geometry (excl. insulation) |

| Primary Purpose | Assembly fit / electrical clearance | Manufacturing consistency / plating control |

| Numeric Mismatch Reason | Outer vs inner reference | Different baseline, not real difference |

In practical cross-reference work, engineers usually:

- Match gauge (AWG or mm²) and stranding (19×34, 7×40, etc.)

- Check temperature and voltage class

- Confirm final OD meets connector or terminal fit

That’s enough to qualify a substitution between MIL and GJB wires.

8. Summary

- At the PTFE level, MIL-DTL-16878 and GJB 773B-2015 are technically equivalent.

- Differences lie in terminology, equipment ecosystem, and measurement methods.

- For practicing engineers, the key is to map Type ET/E/EE ↔ FF4/FF40/FF46 and evaluate compatibility through conductor, temperature, voltage, and OD.

If you can read both standards fluently, you can literally bridge two systems with a single wire.

Final Note — A Little Easter Egg

If you take a closer look through the standards and specifications, you’ll find that the two types of wires shown at the very top of this article actually do not appear in any official document.

Strictly speaking, they represent requirements beyond the existing standards — higher than what either system formally defines.

In other words, both the U.S. and Chinese military specifications are merely baseline frameworks.

In real applications, new wire constructions with superior performance continue to appear as technology advances and user needs evolve.

This is especially true for certain U.S. military wires — honestly, if some customers hadn’t brought the samples to us for processing,

I wouldn’t have believed that wires built to such extreme precision and durability even existed.

Appendix — Glossary of Fluoropolymer Insulations

| Abbrev. | Full Name | Typical Temp Range | Key Properties |

|---|---|---|---|

| PTFE | Polytetrafluoroethylene | –65 ~ +260 °C | Highest temperature resistance; chemically inert; dielectric constant ≈ 2.1 |

| FEP | Fluorinated Ethylene Propylene | –65 ~ +200 °C | Melt-processable, clear, flexible |

| PFA | Perfluoroalkoxy Alkane | –65 ~ +250 °C | Similar to PTFE but processable by heat forming |

| ETFE | Ethylene Tetrafluoroethylene | –65 ~ +150 °C | Tough, abrasion-resistant, used in aerospace harnesses |

| XETFE | Cross-linked ETFE | –70 ~ +200 °C | Radiation-cross-linked ETFE for higher heat and wear resistance |

| PVDF | Polyvinylidene Fluoride | –40 ~ +150 °C | Lightweight, flame-retardant, low-smoke |

| XLPO | Cross-linked Polyolefin | –55 ~ +125 °C | Flexible, low-smoke economic alternative |

Temperature ranges represent typical engineering values and may vary by manufacturer.