1) Introduction

Industrial potentiometers are essential for precise position sensing across a wide range of applications, from factory automation to aerospace.

Yet one thing often puzzles engineers and buyers: Why do some resistive film elements cost just a few dollars, while others—often used in similar applications—can be priced at over a hundred?

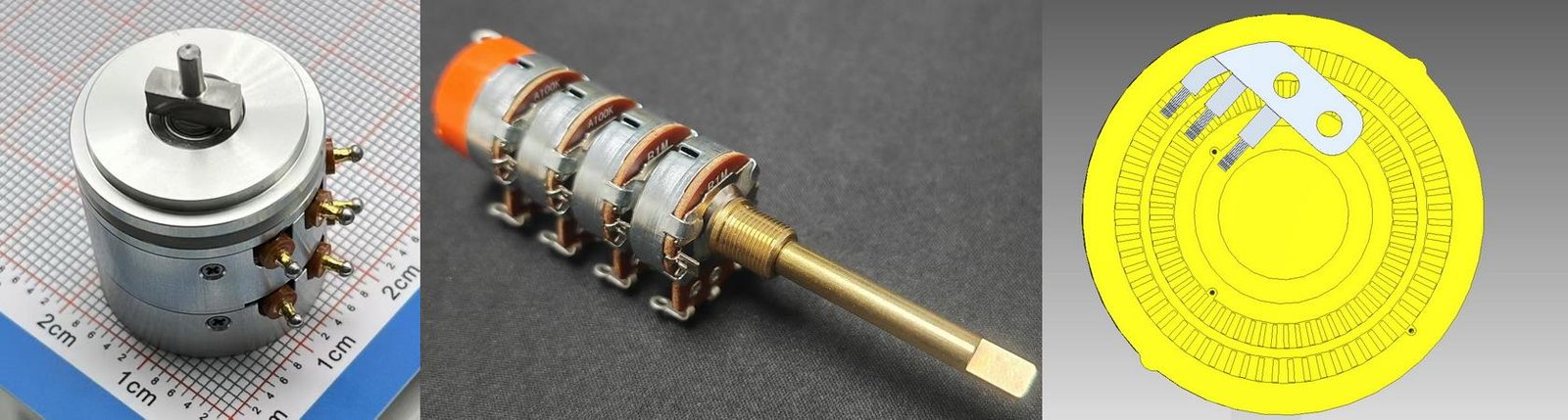

The answer lies in the two main types of resistive film technologies: Thick Film Circuits (carbon film) and Conductive Plastic Potentiometer Elements (e.g., the TE 6915 series). While both are technically "resistive film elements," their differences in structure, materials, manufacturing, and real-world performance are substantial.

In this article, we provide a detailed, side-by-side comparison to help you understand what’s really behind those price tags.

2) Structure and Materials

| Item | Thick Film TPS (Industrial) | Conductive Plastic 6915 (Industrial) |

|---|---|---|

| Resistor Material | Cermet / Carbon Ink | Carbon-based Conductive Polymer |

| Surface Type | Raised, rough | Flush, smooth |

| Brush Structure | Single/Double metal fingers | Multi-finger precious metal |

| Contact Wear | Significant (groove prone) | Minimal (self-lubricating) |

Thick Film Circuits in Industrial Potentiometers

Thick film resistive elements are manufactured by screen-printing cermet or carbon ink paste onto a ceramic or PCB substrate. The resistive arc track, after sintering, is slightly raised above the base. While the structure is robust and suitable for large-scale industrial use, the roughness of the surface means it is more susceptible to wear, especially in high-duty environments with repeated wiper action. End terminations typically use silver-palladium or silver-platinum pastes. The wiper is usually a single or double metal finger—cost-effective, but over time prone to groove formation and increased signal noise.

Conductive Plastic Elements in Industrial Potentiometers (6915 Series)

Conductive plastic elements use a carbon-based conductive polymer, co-molded flush with an engineering plastic substrate. This results in a perfectly smooth and uniform resistive track, maximizing abrasion resistance and mechanical stability—critical for industrial potentiometers that must maintain accuracy over millions of cycles. Multi-finger precious metal wiper designs distribute contact force, minimizing wear and electrical noise. The materials and process are engineered to guarantee stable performance even under harsh industrial conditions.

3) Manufacturing Processes

| Step | Thick Film TPS (Industrial) | Conductive Plastic 6915 (Industrial) |

|---|---|---|

| Forming Method | Screen Printing + Sintering | Co-molded Injection |

| Processing Temp | High (~850°C) | Medium (~160°C) |

| Precision Adjustment | Laser Trimming | Mold precision + factory calibration |

| Batch Suitability | High-volume, low-cost | Small/medium scale, precision |

Thick Film Circuit Manufacturing in Industrial Potentiometers – Detailed Process

The thick film resistive circuit is a mature, cost-effective technology widely adopted in industrial potentiometers, including TPS and various automation sensors. The typical process includes:

- Substrate Cleaning: The ceramic or PCB substrate is meticulously cleaned to ensure adhesion of the resistive paste.

- Screen Printing of Conductive and Resistor Pastes: Precision screen-printing is used to apply metal and resistive pastes, laying out the basic circuit and terminals.

- High-Temperature Sintering: The printed substrates are sintered at approximately 850°C, fusing the materials to create a durable, stable film.

- Laser Trimming: Many industrial potentiometers are laser-trimmed for resistance precision and linearity, meeting industrial accuracy requirements.

- Application of Protective Coating: A final protective layer is applied (glass glaze or polymer), excluding the wiper track, to protect from environmental factors in harsh industrial settings.

Conductive Plastic (6915 Series) Manufacturing in Industrial Potentiometers

The 6915 and similar elements set the standard for high-performance industrial potentiometers:

- Raw Material Preparation: High-purity carbon and polymer blends are prepared for optimal conductivity and durability.

- Co-Molding: Conductive polymer and substrate are simultaneously injected, embedding the track flush with the surface.

- Medium-Temperature Curing: Components are cured at about 160°C for structural and dimensional stability.

- Assembly and Calibration: Multi-finger precious metal wipers and beryllium copper rotors are assembled. Each potentiometer is individually calibrated to industrial/military standards (MIL-PRF-39023).

4) Performance Comparison

| Parameter | Thick Film TPS (Industrial) | Conductive Plastic 6915 (Industrial) |

|---|---|---|

| Linearity Error | ±1% ~ ±2% | ±0.1% ~ ±0.5% |

| Life Cycle | 1M ~ 5M cycles | 10M ~ 100M+ cycles |

| Output Smoothness | Minor ripple | Extremely smooth |

| Temp Drift | ±200~300 ppm/°C | ±80~200 ppm/°C |

Linearity

Industrial thick film potentiometers usually achieve linearity errors between ±1% and ±2%, sufficient for most general automation but limited by their process and design. Conductive plastic industrial potentiometers deliver linearity as low as ±0.1%–0.5% thanks to precision molding and calibration.

Life Cycle

Thick film elements typically endure one to five million cycles—adequate for many factory or automotive settings, but subject to wear. Conductive plastic designs routinely exceed ten million cycles, meeting the long service demands of industrial and military potentiometer applications.

Output Smoothness & Temperature Stability

Conductive plastic potentiometers stand out for extremely smooth output and lower temperature drift, giving them an advantage in precision control, robotics, and mission-critical systems.

5) Application Scenarios & Reliability

| Application Area | Thick Film TPS (Industrial) | Conductive Plastic 6915 (Industrial) |

|---|---|---|

| Main Industries | Automotive, factory automation | Aerospace, defense, robotics, medical |

| Environmental Stress | Moderate to High | Extreme (shock, temp, vibration) |

| Reliability Requirement | Moderate (redundant OK) | Extremely High (zero-failure) |

| Cost Position | Low | High |

Thick Film Applications

Thick film industrial potentiometers are a mainstay for automotive, machinery, and general automation, balancing cost and durability. Their batch-manufacturing model makes them suitable for mass-market, medium-reliability scenarios, but output noise and wear can become limiting factors over time.

Conductive Plastic Applications

Industrial potentiometers built with conductive plastic (such as 6915) serve in the most demanding environments—aviation, defense, medical robotics—where zero failure and ultimate precision are required. Their cost is higher, but their reliability and longevity far surpass other solutions.

6) Cost Structure and Market Positioning

| Factor | Thick Film TPS (Industrial) | Conductive Plastic 6915 (Industrial) |

|---|---|---|

| Material Cost | Low (ceramics, std. pastes) | High (engineered polymers, precious metals) |

| Manufacturing Efficiency | Very high | Moderate |

| Process Complexity | Low | High |

| Testing Requirement | Batch sampling | 100% calibration/testing |

| Typical Unit Price | RMB ¥5~¥20 | $150~$200 USD |

Cost and Market Summary

Thick film potentiometers dominate cost-driven, mass-market industrial applications. Their economic manufacturing model and sufficient reliability make them a strong choice for automotive and factory environments. By contrast, conductive plastic potentiometers command higher prices due to their material, manufacturing, and QA complexity—but they are indispensable where maximum performance and lifetime are paramount.

7) NOLELC’s Production Capability for Industrial Potentiometers

NOLELC is an experienced manufacturer of industrial potentiometer and sensor elements. We offer full-scale production for conductive plastic resistive films and thick film circuits, supporting customization with low minimum order quantities and standard product delivery within 45 days. Whether you need reliable alternatives to major global brands or fast, flexible support for new industrial projects, NOLELC delivers both technical quality and rapid turnaround for industrial potentiometers.

8) Conclusion

Both thick film and conductive plastic elements are essential to the industrial potentiometer field, but serve distinct roles. The former is unmatched for cost control and mass production; the latter is the benchmark for reliability, accuracy, and long-term performance. As automation and system complexity increase, choosing the right resistance element is critical to industrial potentiometer success.