1) Introduction

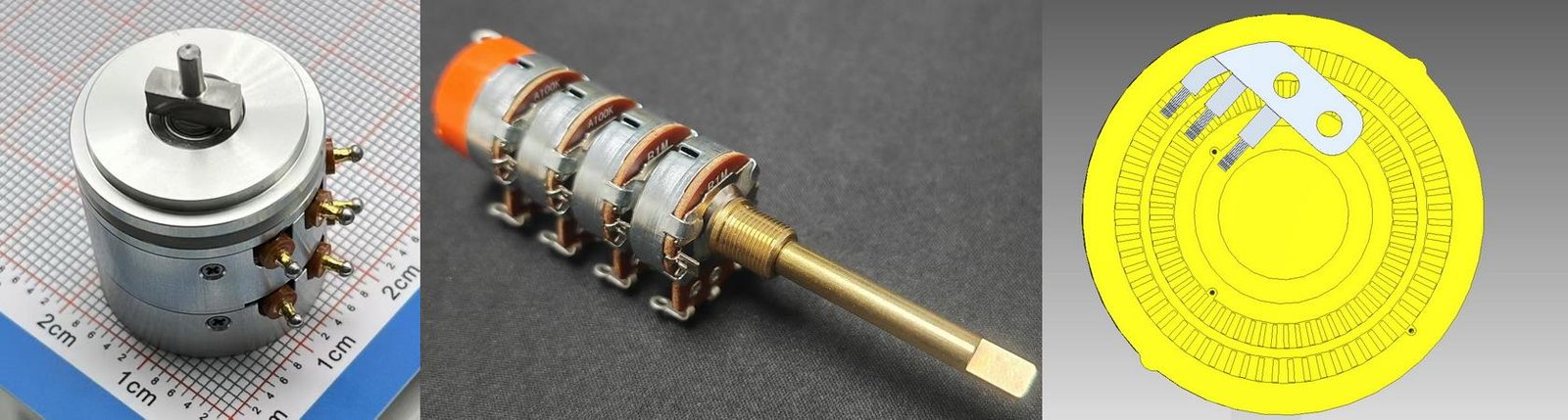

Brushes play a critical role in potentiometers, sensors, and other sliding electrical contact devices. The choice of brush material directly affects contact resistance, service life, wear resistance, and signal stability. In the industry, three main types of brush materials are commonly used: three-element alloy brushes, six-element alloy brushes, and multi-wire precious metal brushes. This article compares their structure, material properties, performance, and typical applications.

2) Key Terms

| Term | Description |

|---|---|

| Brush | Sliding electrical contact component |

| Three-element (ternary) alloy brush | Alloy brush with three main elements |

| Six-element alloy brush | Alloy brush with six main elements |

| Multi-wire (multi-finger) brush | Brush with multiple fine wires in parallel |

| Precious metal brush | Brush made with precious metal alloys |

| Contact resistance | Electrical resistance at the brush contact |

| Wear resistance | Ability to withstand abrasion over time |

| Service life | Usable cycles before failure |

| Potentiometer | Precision adjustable resistor |

| Position sensor | Device for measuring position/angle |

| Slip ring | Rotary electrical connector |

3) Three-Element Alloy Brushes

Three-element alloy brushes are commonly made from precious metal alloys such as gold-silver-copper (Au-Ag-Cu) or palladium-silver-copper (Pd-Ag-Cu). These alloys balance excellent electrical conductivity with good wear resistance and moderate cost. Gold provides outstanding oxidation resistance, while silver and copper add strength and durability. Typical applications include conductive plastic potentiometers, precision sensors, and micro-motors. Service life generally ranges from several hundred thousand to a few million cycles, depending on operating conditions.

4) Six-Element Alloy Brushes

Six-element alloy brushes utilize advanced multi-element precious metal alloys, for example: Pd-Ag-Cu-Au-Pt-Zn. The inclusion of platinum and gold enhances hardness, oxidation resistance, and long-term stability. These brushes deliver very low contact resistance, high wear resistance, and stable performance in a wide range of environments.

Six-element alloy brushes are designed to meet the requirements of high-reliability applications, such as automotive sensors, industrial automation, medical devices, and precision potentiometers. In practical use, their reliability and service life are on par with those of leading international brands, such as Heraeus (Helix) multi-wire precious metal brushes.

5) Multi-Wire Precious Metal Brushes (Industry Leading)

International brands like Heraeus (Helix) are renowned for their patented multi-wire precious metal brush technology. These brushes feature numerous ultra-fine wires welded or mounted in parallel, maximizing the number of contact points for optimal electrical redundancy and stability. Multi-wire brushes are widely used in automotive throttle sensors, steering angle sensors, high-end encoders, micro-motors, and medical equipment.

Our six-element alloy brush products are engineered and manufactured to meet the same performance standards, providing a reliable and high-quality alternative to imported brushes in most high-end applications.

6) Comparison Table

| Comparison Aspect | Three-Element Alloy Brush | Six-Element Alloy Brush | Helix/Heraeus Precious Metal Brush (Top-tier) |

|---|---|---|---|

| Main Alloy Elements | Ternary precious metal alloys, typically Au-Ag-Cu or Pd-Ag-Cu. For example: Au70%–Ag25%–Cu5%, Pd70%–Ag30%, Pd70%–Cu30%, etc. | Six-element precious metal alloys, typically Pd-Ag-Cu-Au-Pt-Zn. For example: Pd35%–Ag30%–Cu14%–Au10%–Pt10%–Zn1% (Palliney-6), or gold-based multi-element alloys. | Multi-element precious metal alloys, mainly Pd-Ag-Cu-Au-Pt-Zn, or Au-based/Ag-based multi-element alloys. Proprietary or customized international standard compositions. |

| Conductivity | Excellent: High conductivity, stable signal output. | Excellent: Multiple contact points, extremely low and stable contact resistance (milliohm level). | Excellent: Multi-wire and proprietary alloy, ultra-low and stable contact resistance (milliohm level), highly reliable signal transmission. |

| Wear Resistance & Service Life | Good: Moderate wear resistance, typical service life up to several million cycles. | Excellent: High hardness and wear resistance, service life up to tens of millions of cycles under ideal conditions. | Outstanding: Multi-wire distributes wear, practical service life exceeds 2 million cycles; under optimal conditions, up to tens of millions of cycles. |

| Stability (Oxidation/Corrosion) | Good: Precious metals provide oxidation and corrosion resistance; clean, stable environments recommended. | Excellent: Contains Au, Pt and others, strong oxidation and arc resistance, stable under high temperature and humidity. | Excellent: Special corrosion-resistant alloy, stable operation even in fuel and harsh media, very robust in a variety of environments. |

| Unit Cost | Moderate: Higher than standard materials but lower than six-element or imported brushes. | High: Contains Au, Pt and other precious metals, relatively high cost. | Very High: Imported brand, multi-precious metal formula, highest cost (for high-value or critical applications). |

| Typical Applications | Precision potentiometers, mid-range automotive sensors, standard slip rings, general industrial controls. | Aerospace sensors, military/research potentiometers, key automotive sensors, medical and precision devices. | Automotive electronics (throttle, steering, pedal sensors), medical devices, aerospace, high-end encoders, micro brushed motors, high-speed slip rings, advanced industrial and communication equipment. |

7) Application Scenarios

- Automotive Electronics: Throttle position sensors, steering angle sensors, accelerator pedal sensors, fuel level sensors

- Industrial & Defense: High-resolution encoders, slip rings, micro-motors, precision potentiometers

- Medical Equipment: Medical imaging devices, diagnostic equipment

- Precision Instruments: Laboratory and industrial controls, high-end audio potentiometers

8) Conclusion

Three-element alloy brushes, six-element alloy brushes, and multi-wire precious metal brushes represent the mainstream brush technologies for precision potentiometers and sensors. While international brands like Heraeus (Helix) have set the industry benchmark with their multi-wire technology, our six-element alloy brush products are engineered and manufactured to deliver comparable reliability, stability, and service life.

For customers seeking a high-quality and cost-effective alternative to imported brands, our solutions are ideal for a wide range of demanding applications. We welcome technical discussions and custom projects for unique requirements.