Choosing the right potentiometer manufacturer is crucial for the success of any electronics project.

Engineers and purchasing managers each have their own theories when evaluating potential suppliers, but these are often difficult to fully verify in practice.

A reliable manufacturer should offer a broad range of options (including custom potentiometers for specialized uses) and uphold high quality standards.

Factors like product quality, customization capabilities, and fast delivery performance can make all the difference in your project’s outcome.

Moreover, potentiometer technology continues to advance. Today’s potentiometers have evolved beyond simple knobs and dials into high-precision, sensor-grade devices.

This means that manufacturers need cutting-edge design and precision manufacturing processes to meet modern demands.

Quality certifications (such as ISO standards) and a strong industry reputation are good indicators of a manufacturer’s reliability.

In this guide, we’ll explore the key factors—such as technical features—to help you find the right potentiometer manufacturer.

1) A Brief Overview of Potentiometer Functions

In essence, they act as adjustable resistors that allow you to regulate voltage or current flow.

By turning a knob or sliding a lever on a potentiometer, you can adjust signal levels—for example, dimming a light or changing the volume on audio equipment.

This ability to fine-tune electrical output is essential for the proper functioning of many devices and systems.

These components come in various forms, each offering unique benefits for specific applications.

Potentiometers are commonly used to:

- Adjust signal levels in circuits (voltage, current, etc.)

- Control audio volume and other settings in consumer electronics

- Fine-tune circuit elements for calibration and testing in equipment

Selecting the right potentiometer starts with knowing your application’s requirements.

By matching the potentiometer type and specifications to your needs, you ensure optimal performance and durability in your electronic design.

In short, a solid grasp of potentiometer basics will inform better choices when evaluating manufacturers and their product offerings.

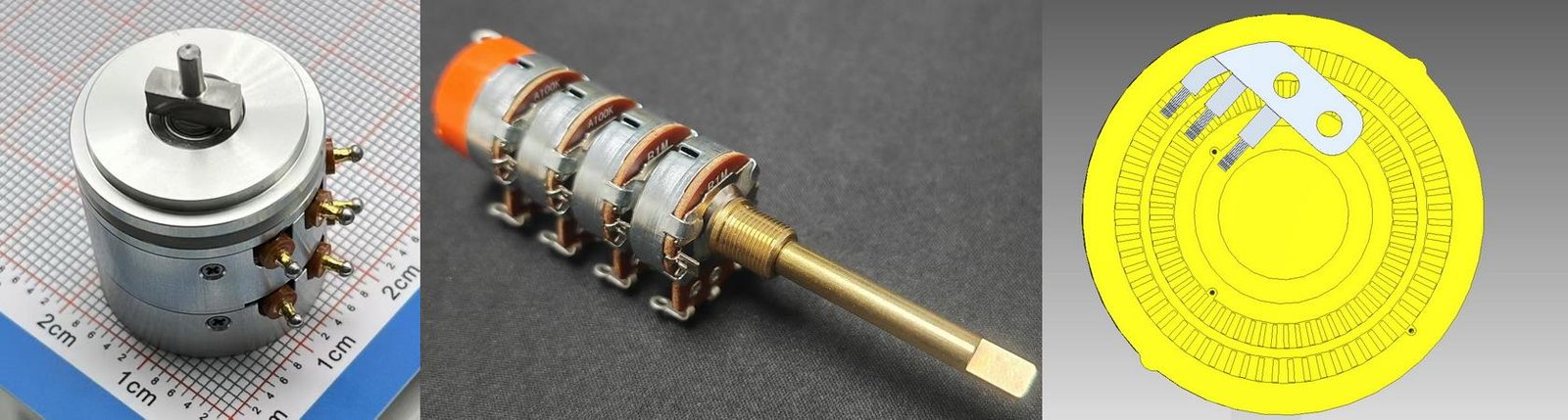

2) Key Potentiometer Types and Their Applications

There are several key types of potentiometers, each suited to different uses.

Choosing the correct type for your project is crucial for optimal functionality.

Rotary Potentiometers: These are the familiar knob-operated pots that provide smooth, continuous adjustment.

By twisting the shaft, you vary the resistance, which makes them ideal for settings that require gradual control.

Rotary potentiometers are widely used in applications like audio equipment (e.g. volume knobs on amplifiers and radios) where an easy, circular motion adjusts the output.

They offer reliable performance for any interface that benefits from a dial-type control.

Linear Potentiometers: These potentiometers adjust value with a straight-line sliding motion.

Instead of turning a knob, you move a slider to change resistance.

Linear potentiometers are perfect for applications that involve a direct linear displacement—for instance, as faders on a mixing console or position sensors in machinery.

Digital Potentiometers: Unlike the traditional mechanical types, digital potentiometers are electronic devices that simulate the function of a potentiometer using up/down signals or software commands.

These advanced pots are ideal for remote or automated adjustments since they can be controlled by a microcontroller or computer.

Digital potentiometers offer high precision and stability (no mechanical wear and tear), and you’ll commonly find them in modern electronic systems that require programmable tuning.

Choosing the proper type of potentiometer ensures your device functions efficiently and reliably.

3) Modern Trends: Potentiometers Evolving into Sensor-Grade Components

Potentiometer technology has come a long way, blurring the line between a simple manual control and a sophisticated sensor device.

Many modern potentiometers are now designed and manufactured to perform with sensor-grade precision and reliability.

This evolution is driven by the demands of advanced electronics and modern factory processes.

Key trends include:

- Transition to digital and contactless designs

- Integration with smart systems (IoT and automation)

- Precision manufacturing and advanced materials

Manufacturers keeping up with these trends can provide digital solutions, high-precision assemblies, and improved materials—reflecting a commitment to precision manufacturing and continuous improvement.

Nolelc, for example, utilizes laser trimming, conductive plastic elements, and rigorous testing to ensure every potentiometer meets the demands of modern smart devices and sensor upgrades.

4) What to Look for in a Potentiometer Manufacturer

When it comes to choosing a potentiometer manufacturer, there are several important factors to evaluate.

Not all suppliers are equal—the right partner will combine technical capability with reliability and service.

Product Range and Variety: First, examine the range of potentiometer types and specifications the manufacturer offers.

A reputable company should provide a broad selection—including rotary, linear, multi-turn, and digital potentiometers—to cater to different design needs.

A wide product range means the manufacturer is experienced in serving diverse industries and can likely meet your specific application requirements.

If you need a unique or uncommon potentiometer, a manufacturer with a large catalog (and the ability to do custom variants) will be invaluable.

Industry Reputation and Experience: The manufacturer’s track record in the industry is a strong indicator of quality.

Companies that have been in the business for many years or decades have had time to refine their production processes and build trust with clients.

Look for signs of a good reputation: long-term client relationships, positive testimonials or case studies, and a history of delivering on complex projects.

An experienced manufacturer is more likely to have encountered and solved challenges similar to your own, resulting in a smoother experience for you.

Quality Standards and Certifications: Quality should be a top priority when evaluating manufacturers.

Check what standards of quality control the company adheres to. Certifications like ISO 9001 indicate that the manufacturer follows internationally recognized processes to maintain high quality and consistency.

Additionally, compliance with industry-specific standards (for example, automotive or aerospace quality standards) can be important if your project is in those fields.

A manufacturer that invests in quality assurance will deliver potentiometers that perform as specified and are safe and reliable.

Nolelc, for example, employs precision manufacturing techniques and uses premium materials (such as precious metal alloy contacts and robust spring bases) to ensure each potentiometer is durable, low-noise, and reliable.

Technical support can be invaluable—you may need guidance on selecting the right potentiometer model, help with troubleshooting integration issues, or advice on maintenance and lifespan.

Manufacturers that offer direct access to engineering support or have dedicated account managers for technical clients show that they stand behind their products.

After-sales service (like handling any issues, warranty claims, or replacements) is also crucial, especially in a B2B context where downtime can be costly.

A company that is responsive and helpful when you have questions or problems is worth its weight in gold.

In summary, as you vet potential suppliers, keep in mind a few key points:

- Range of potentiometer types available

- Quality certifications and standards

- Technical support and service

A manufacturer that scores well on all these fronts is likely to be a strong partner.

Nolelc, for example, exemplifies these qualities by combining a broad product selection, decades of expertise, strict quality standards, and attentive customer support.

5) Evaluating Potentiometer Design and Replication Capabilities

Another crucial aspect of a potentiometer manufacturer is its design and Replication capabilities.

BOURNS 3590 and Copal M22L10 are great examples—they look almost identical, have similar performance, and both come from reputable companies in the industry.

The ability to customize and innovate can greatly influence whether a manufacturer can meet your unique requirements.

Not every project can use off-the-shelf components; in many cases, you might need a tailored solution.

Here’s what to evaluate regarding design and customization prowess:

Custom Design and Engineering Services: Determine if the manufacturer offers custom potentiometer design services or the flexibility to modify existing products.

A strong design team can collaborate with you to create a potentiometer that fits non-standard specifications, unusual form factors, or specific performance characteristics.

This is especially important for niche applications or innovative projects where a generic component won’t do.

Manufacturers that welcome custom requests show that they are solution-oriented and capable of tackling engineering challenges.

They will typically have dedicated engineers who understand potentiometer design from the ground up—from adjusting resistance curves and tapers to choosing specialized materials for wipers and tracks.

Commitment to Innovation: Innovation in the potentiometer field could mean anything from developing new materials that increase lifespan, to integrating electronics for smarter control, to improving manufacturing techniques for better precision.

Gauge how much the manufacturer invests in developing their products. Do they frequently release improved versions or new series of potentiometers?

Are they keeping up with trends like digital potentiometers or sensor integration?

A company that emphasizes innovation will be able to offer more advanced solutions.

This often translates to better performance for you—for instance, potentiometers with lower noise, higher temperature stability, or more compact designs.

Research & Development (R&D) and Advanced Tools: Leading potentiometer manufacturers often have a dedicated R&D department and modern design tools.

Companies that prioritize quality typically use precision machining and comprehensive sample testing.

This results in cutting-edge products and continuous improvement.

By choosing a manufacturer with strong R&D, you benefit from the latest techniques and a forward-thinking approach.

For example, a company that uses automated fabrication and laser trimming can achieve very tight resistance tolerances and matching between components—a sign of engineering excellence.

Likewise, manufacturers engaged in material research might offer potentiometers with improved conductive plastics or hybrid designs (part mechanical, part digital) that give you an edge in performance.

When assessing a manufacturer’s design capabilities, keep in mind a few key factors:

- Ability to provide custom potentiometer designs

- Focus on innovation and improvement

- Strong R&D investment

Choosing a manufacturer with excellent engineering capabilities means you’re not just buying a part—you’re gaining a partner who can help tailor and refine the component to perfectly suit your project.

This often leads to superior outcomes, as the potentiometer will be optimized for your application rather than a one-size-fits-all solution.

6) Quality Standards and Certifications

Product quality is paramount in electronic components, and potentiometers are no exception.

A potentiometer might be a small part, but if it fails or performs inconsistently, it can have outsized effects on your device’s performance.

That’s why it’s essential to choose a manufacturer that adheres to strict quality standards and holds relevant certifications.

Importance of Quality Standards: Quality standards (like ISO certifications) provide assurance that a manufacturer follows well-defined, audited processes for production and quality control.

For instance, ISO 9001 certification indicates that the company has a robust quality management system in place.

When a manufacturer is ISO-certified, you can have greater confidence in the consistency and reliability of each unit that comes off their production line.

Consistency, Reliability, and Safety: A manufacturer that follows high quality standards will likely produce potentiometers with tighter tolerances, less variance unit-to-unit, and better overall performance.

These companies often implement 100% testing of critical parameters and may conduct life-cycle tests to ensure longevity.

They also tend to have traceability systems, so every potentiometer can be traced back to its batch and production conditions.

All of this means fewer surprises for you—the parts will perform as advertised, and the risk of early failures or inconsistencies is minimized.

Additionally, manufacturers with rigorous standards often use top-grade materials and components.

Nolelc, for instance, maintains an ISO-certified production process and uses premium materials (such as precious metal contact brushes and durable alloys) to ensure each potentiometer meets strict quality benchmarks.

This dedication results in potentiometers that are not only precise in initial performance but also reliable over the long run, even in demanding environments.

7) Customization and Technical Support

For many projects, the ability to get custom potentiometers or specialized support from the manufacturer can be a game-changer.

Not every application can use a standard, off-the-shelf component, and even if it can, you might benefit from expert guidance to pick the optimal solution.

Manufacturers that excel in customization and support set themselves apart by truly partnering with their customers.

Customization Capabilities: A manufacturer offering custom potentiometer design can provide tailored solutions to meet your specific needs.

This might include altering the resistance value or taper of a potentiometer, creating a unique form factor or mounting configuration, using a special sealing or housing for harsh environments, or even developing an entirely new potentiometer assembly.

The benefit of customization is that the component will fit your application perfectly, potentially improving performance and integration.

When evaluating this, see how the manufacturer handles custom requests: Do they have a formal process for custom orders? What minimum order quantities (if any) are required?

How experienced are they in delivering custom designs (you might look for case studies or ask for examples)?

A flexible manufacturer will work with you to understand your requirements and propose a solution—this collaborative approach can lead to a better end product than trying to force-fit a generic part.

Nolelc, for example, offers extensive custom design services; our engineering team works closely with clients to develop potentiometers tailored to unique specifications, ensuring that even niche or innovative projects get a perfect fit.

Comprehensive Technical Support: Technical support goes hand-in-hand with customization.

A reliable manufacturer should provide assistance not just in selling you a part, but in making sure it works for you.

This support can start early, with pre-sales engineering consultation to help choose the right potentiometer (or to brainstorm a custom approach if needed).

It continues through installation and usage—for instance, providing datasheets, wiring diagrams, or even on-call support to answer any implementation questions.

After you’ve received the product, good manufacturers will also offer after-sales support: this could include troubleshooting help if something isn’t working as expected, quick replacements or fixes if a unit is faulty, and honoring warranties without hassle.

Strong technical support is particularly important in B2B relationships because your projects might be complex and time-sensitive.

Knowing that the manufacturer has your back can save you time and reduce stress.

Look for companies that are responsive in communication, have knowledgeable staff (you should be able to talk to an engineer when needed, not just a salesperson), and possibly even offer training or documentation to help you use their products effectively.

When evaluating a manufacturer’s customization and support offerings, ensure they can provide:

- Custom potentiometer design services

- Hands-on technical support

- Prototypes or samples for testing

Manufacturers that check these boxes are likely to be proactive and customer-focused.

Strong technical support and flexible customization options can significantly enhance your experience and the success of your end product.

They effectively become an extension of your own development team.

For instance, Nolelc exemplifies this approach: we provide one-on-one technical consulting, rapid prototype turnaround for custom designs, and ongoing support to ensure our potentiometers integrate seamlessly into clients’ projects.

8) Cost, Lead Times

While technical specifications and quality are vital, practical considerations like cost and delivery time are also key when choosing a potentiometer manufacturer.

In a business setting, you have budgets to meet and deadlines to hit. The goal is to balance cost with quality and ensure a steady supply of components.

Balancing Cost and Quality: It’s natural to consider pricing when comparing manufacturers. However, the cheapest option is not always the best choice in the long run.

Extremely low-cost potentiometers might save you money upfront but could cost you more if they fail early or perform inconsistently.

When evaluating cost, look at the value you’re getting: a slightly higher-priced potentiometer from a reputable manufacturer may offer significantly better longevity and performance, saving you from downtime or replacement costs later.

Think of it as an investment in your product’s reliability.

That said, you should expect competitive pricing for the quality level offered.

If you have large volume needs, discuss pricing breaks or long-term agreements – many manufacturers offer discounted pricing for bulk orders or repeated business, which can help manage costs.

Lead Times: Equally crucial is the manufacturer’s ability to deliver potentiometers when you need them.

Long lead times or unpredictable delivery schedules can stall your production.

When assessing manufacturers, inquire about their typical lead times for both standard orders and custom orders.

Do they keep a stock of common potentiometer models for immediate shipment, or do they build to order every time?

Manufacturers with efficient production processes can often fulfill orders faster.

Fast delivery can be a major advantage, especially if you operate on just-in-time manufacturing principles or need quick turnarounds for project development.

For instance, Nolelc’s streamlined production enables us to offer very fast delivery times, even on custom potentiometer orders – helping our clients avoid downtime and keep their projects on schedule.

When weighing cost and lead times, consider the following:

- Pricing models

- Production capacity and speed

Selecting a manufacturer with reliable delivery ensures you’ll get your potentiometers when you need them, without unexpected surprises.

It reduces the risk of production holdups on your end.

Ultimately, the best partner is one who provides a good balance of competitive pricing, efficient production, and dependable delivery.

This way, you can keep your project on budget and on schedule.

9) Making the Final Decision: Tips and Best Practices

After gathering information on technical capabilities, quality, support, and delivery, you’ll want to compare your top candidates and make a well-informed final decision.

Here are some tips and best practices to guide you through that process:

Do a Holistic Comparison: Create a checklist or spreadsheet of all the factors discussed – product range, customization ability, certifications, support, cost, lead time, etc.

Place each potential manufacturer side by side and see how they stack up in each category.

This visual comparison can make it clearer which manufacturer excels overall or in the areas most important to you.

Sometimes a manufacturer might not be the leader in every single category, but if they shine in the ones that matter most for your project (while meeting baseline expectations in others), they could be the right choice.

Speaking directly to an existing customer of the manufacturer (if you have the opportunity) can provide candid information about any challenges they’ve faced.

Also, review their warranty or return policy. Reputable manufacturers will typically offer a warranty on their products – understand what it covers and the process for making a claim if something goes wrong.

A fair, clear warranty policy is a good sign that the company stands behind its quality.

It’s also wise to confirm how they handle any non-conforming parts or DOA (dead on arrival) components – the last thing you want is to be stuck with faulty parts and no support.

By doing your due diligence in these areas, you’ll increase the confidence in your final choice.

The goal is to select a potentiometer manufacturer that not only meets the technical specs but is also a trustworthy business partner.

These steps will help ensure your selection aligns with both your technical requirements and your business priorities.

Taking a bit of extra time in the decision phase can save a lot of headaches later, as you’re far more likely to end up with a reliable supplier and a smooth procurement process.

10 Conclusion

Choosing the right potentiometer manufacturer is a critical step that can greatly influence the success of your electronic projects.

The best manufacturer for you will be one that offers the technical capabilities you need – whether that’s a wide array of standard potentiometers or the ability to engineer a custom solution – while also maintaining top-tier quality and support.

By carefully assessing factors such as design innovation, product quality, certification, customization services, and fast delivery, you can make an informed decision and forge a partnership that benefits your business in the long run.

Remember to balance cost with quality and reliability. It’s often worth investing in a slightly more expensive component from a manufacturer with a proven track record if it means avoiding failures and downtime later.

The right manufacturer will provide not just components, but confidence – knowing that the potentiometers you receive will perform as expected and that you have support if any issues arise.

In a B2B context, this reliability and trust are invaluable.

At Nolelc, we understand these priorities and strive to meet all the criteria discussed above.

We pride ourselves on our product quality, precision-focused manufacturing, robust customization capabilities, and fast delivery times.

Our team is dedicated to being a reliable partner – providing high-quality electronic components and one-on-one technical support to ensure they integrate seamlessly into your projects.

By choosing a manufacturer that aligns with your needs (like Nolelc), you can secure a smooth supply of potentiometers that will help your designs perform at their best.

With the right partnership in place, you’ll be well-equipped to tackle your next project with confidence and success.