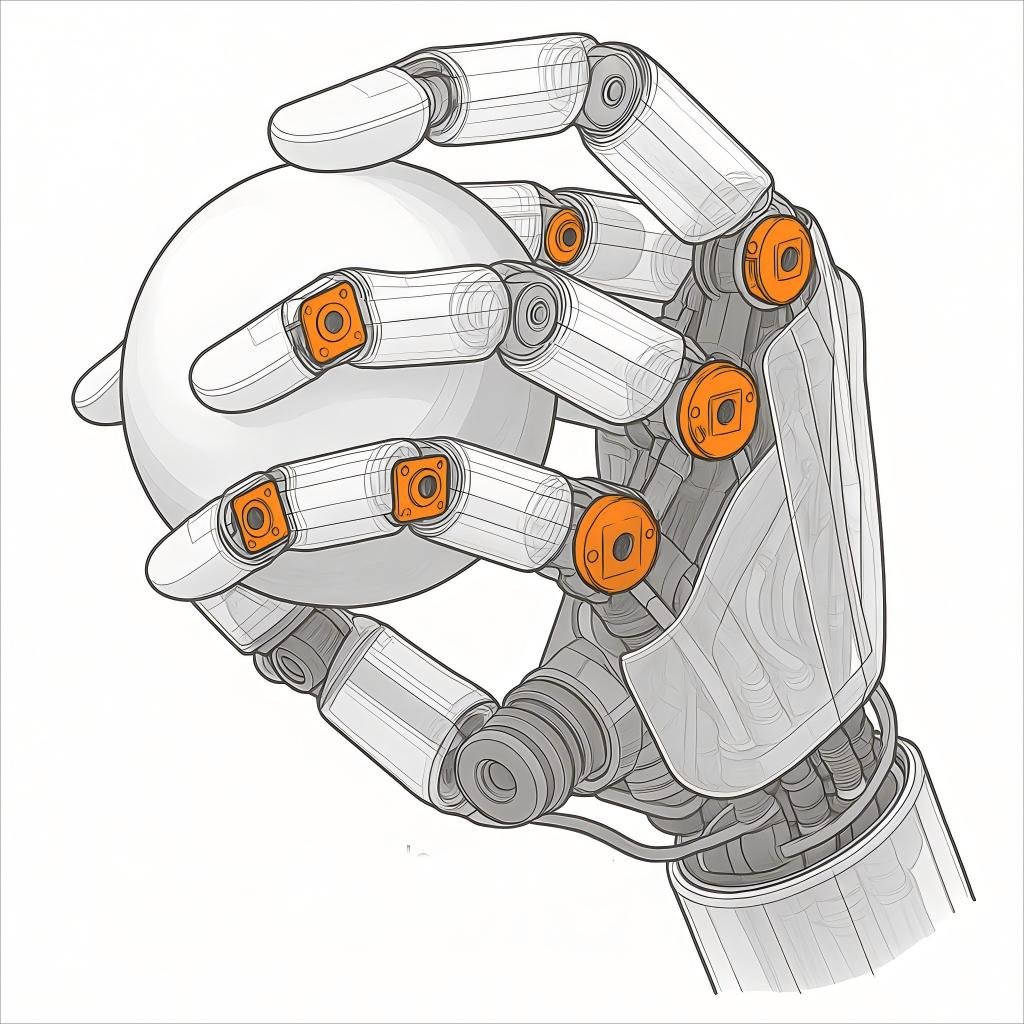

The image shows conductive-plastic hollow-shaft angle sensors in multiple form factors—elongated-slot flange, square flange, and mini through-hole—to cover proximal, middle, distal finger joints and the wrist in simulation hands. Coaxial hollow mounting simplifies wiring; outputs are smooth and low-friction, rated for −65 to +125 °C and high-cycle testing.

— Based on Conductive Plastic Resistive Element Structure and Feedback Characteristics

1. Introduction

Simulation robotic hands are among the most anthropomorphic systems in robotics.

They require flexible and coordinated bending motions, as well as precise angular feedback to achieve natural and smooth motion control.

In the design and manufacture of simulation robotic hands, the selection of angle sensors directly affects system accuracy, stability, and overall lifespan.

Conductive plastic hollow-shaft angle sensors, featuring lightweight design, continuous output, and excellent linearity, have become an ideal solution for such systems.

2. Advantages of Conductive Plastic Hollow-Shaft Angle Sensors

These sensors are made of high-resolution conductive plastic resistive elements and feature a central hollow shaft design that can be directly mounted on the joint’s rotation axis—ideal for compact robotic hand structures.

They detect angular position through resistance variation and provide stable rotational feedback for each joint.

Key Advantages:

- Compact design: the hollow shaft fits directly on the joint axis with minimal space.

- High linearity: typical accuracy up to ±0.3%, ensuring precise bending feedback.

- Smooth signal output: continuous, jitter-free response for natural motion algorithms.

- Low friction: minimizes load on servo actuators and improves responsiveness.

- Long life: over 5 million rotational cycles, ideal for research and educational use.

In simulation robotic systems, these sensors are used exclusively for angular detection, providing rotational position feedback rather than linear or pressure signals.

3. Comparison with Other Sensor Types

In the field of angle detection, common alternatives include magnetoelectric, Hall-effect, and optical encoder sensors.

Each type has advantages, but all have limitations in compact, precision finger joints of simulation robotic hands.

| Type | Advantages | Limitations | Suitability for Robotic Hands |

|---|---|---|---|

| Conductive Plastic Hollow-Shaft Angle Sensors | Continuous output, high resolution, compact structure | Analog signal may require shielding | ✅ Best suited for finger joint systems |

| Magnetoelectric Sensors | Non-contact, dust-resistant | Susceptible to magnetic interference, unstable at small angles | ⚙️ Suitable for larger joints or wrist areas |

| Hall Sensors | Low cost, vibration-resistant | Limited resolution, thermal drift | ⚙️ Suitable for low-precision or educational systems |

| Optical Encoders | High resolution, digital output | Bulky, high installation precision required | 🚫 Not suitable for compact finger joints |

In summary, conductive plastic hollow-shaft angle sensors remain the most balanced and practical choice for smooth and precise feedback in robotic finger simulations.

4. Applications in Robotic Finger Simulation

Each robotic finger typically contains three joints: base, middle, and tip.

A conductive plastic hollow-shaft angle sensor is installed at each joint’s axis to continuously monitor bending angles and send feedback to the control system.

- Proximal joint: measures wide bending angles, typically 0–180°.

- Middle joint: ensures midrange angle feedback for smooth motion transitions.

- Distal joint: works with force-feedback modules for gripping or tactile simulation.

The signals are processed by the control system and transmitted to the simulation platform for posture synchronization, error correction, and algorithm validation—making robotic motion closely resemble that of a human hand.

5. Basic Application Example

Perspective illustration of a robotic simulation hand equipped with hollow-shaft angle sensors at each joint. Each orange module represents a conductive plastic-based angle sensor that detects finger and wrist rotation, providing smooth and accurate motion feedback for realistic simulation control.

A five-finger simulation robotic hand for education or algorithm development typically includes 15–16 conductive plastic hollow-shaft angle sensors.

Each of the four fingers has three joints, while the thumb may have two or three active joints depending on the design.

The deepest carpometacarpal (CMC) joint near the wrist enables thumb opposition motion.

An additional sensor at the wrist detects overall rotation and posture.

System Highlights:

- Finger motion latency <5 ms with natural bending feedback.

- Linearity error within ±0.3%.

- Hollow shaft allows signal or air lines to pass through for neat wiring.

- Compatible with digital twin or 3D simulation systems for real-time motion display.

6. Selection and Integration Guidelines

When integrating simulation robotic hands, sensor specifications must align with mechanical structure, interface type, and required precision.

Key Considerations:

- Shaft diameter: common hollow sizes 4 mm, 6 mm, 8 mm—match joint shafts.

- Output type: 0–5 V analog preferred for better controller compatibility.

- Linearity & repeatability: choose sensors with ≤ ±0.5% linearity.

- Friction & torque: low-friction models reduce servo load.

- Protection: IP54 or above for dust and moisture resistance.

7. Technical Highlights of NOL Conductive Plastic Film Technology

NOL’s proprietary conductive plastic film and resistive elements use advanced polymer composites and thick-film techniques, ensuring both high stability and flexibility, and are widely used in hollow-shaft angle sensors and precision potentiometers.

Key Technical Advantages:

- High linearity: typically ±0.25%, customizable to ±0.15%.

- Wide temperature range: operates reliably from –70 °C to +125 °C.

- Low contact noise: multilayer composites ensure smooth signal output.

- Long durability: over 5 million rotational cycles.

- Stable TCR: below ±200 ppm/°C for consistent output.

- Flexible customization: supports various geometries, resistance curves, or multi-track layouts.

- Package compatibility: fits aluminum, plastic, or hybrid ceramic housings.

With these material and process advantages, NOL’s conductive plastic film technology ensures excellent electrical stability and environmental reliability—delivering consistent, long-term performance in high-sensitivity robotic simulation applications.